Explore Our Products

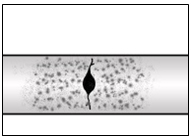

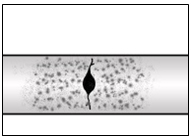

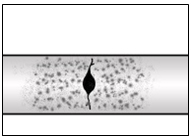

ELECTRIC MOTOR CLEANER

SEALXPERT ELECTRIC MOTOR CLEANER

FEATURES:

- Neutral, not water soluble

- Has no corroding effect

- Excellent long lasting rust protection

- Non-conductive

- Excellent dissolving ability

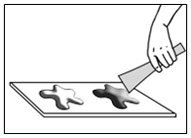

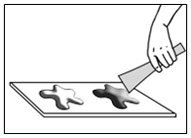

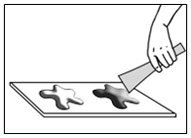

APPLICATION:

- Safe to use on all metals and alloys and most painted/varnished surfaces

- For cleaning of all electrical equipment including motors, generators, switchgears, electrical cables, switches, contacts, electronics, compressors, relays, coils, alarms and etc.

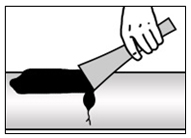

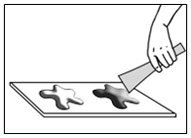

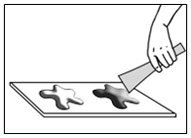

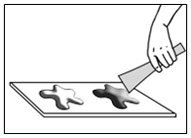

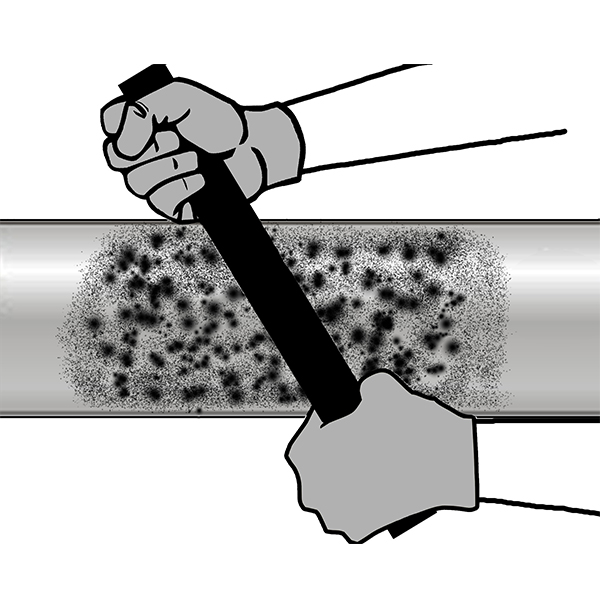

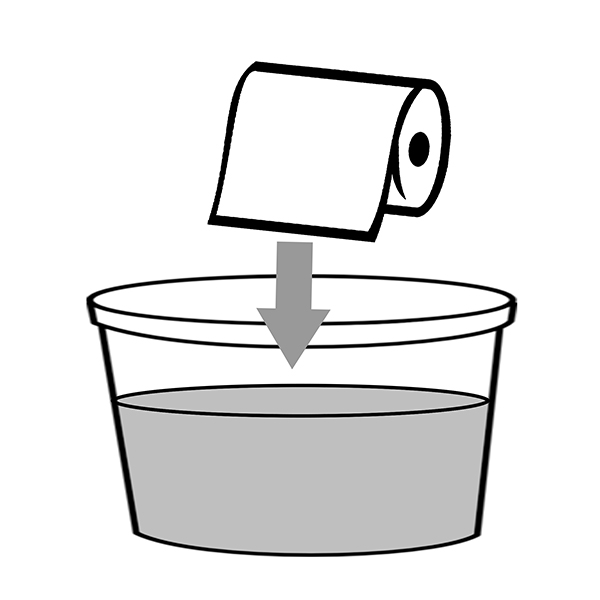

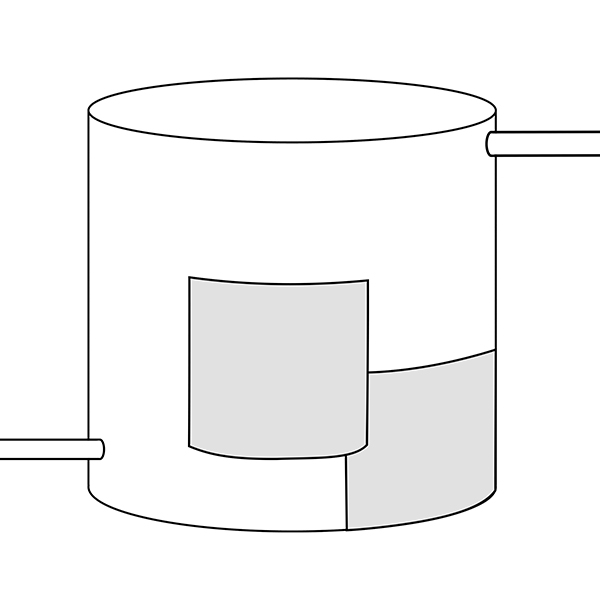

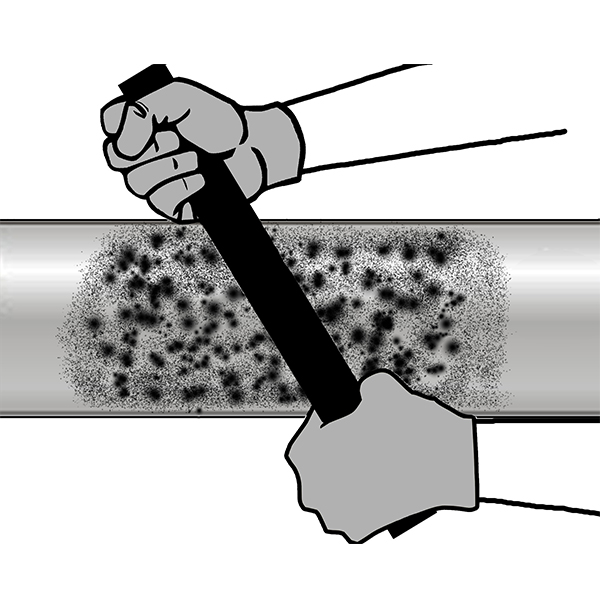

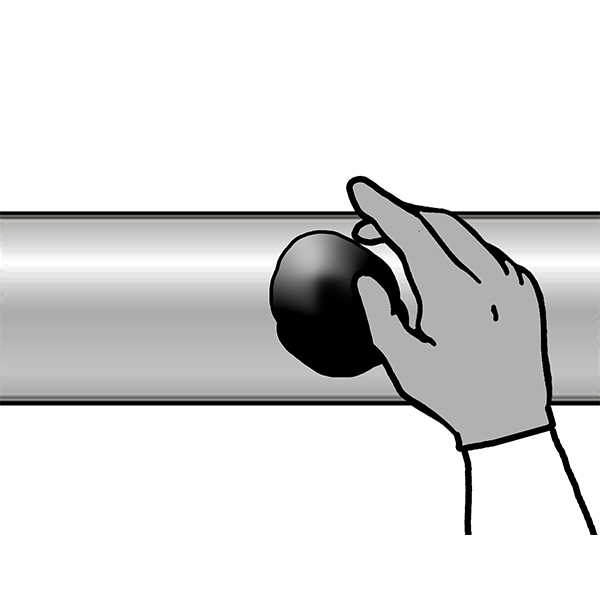

CARBON REMOVER

SEALXPERT CARBON REMOVER

FEATURES:

- Quickly dissolves deposits containing carbon, resins or varnishes

- Simple and economical to use

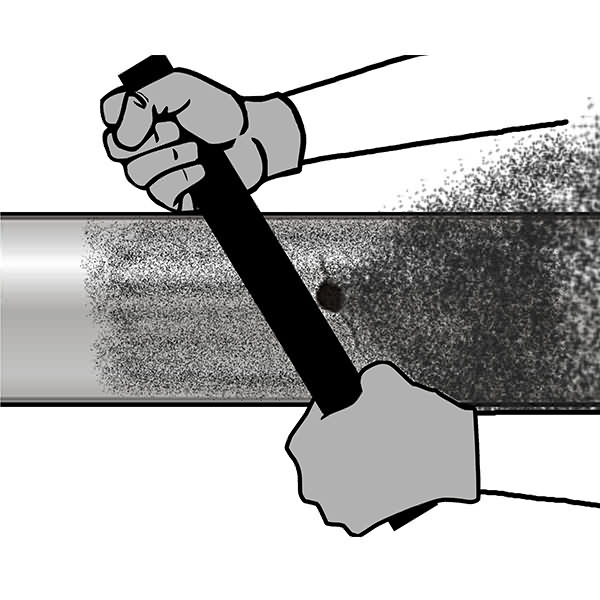

APPLICATION:

- Removes carbon type deposits from burner tips, fuel injectors and all components fouled by carbon, resin or varnishes

- Removes carbon based deposits from fuel and lube oil filters

SEALXPERT CARBON REMOVER

PACKAGE:

- 18 litres

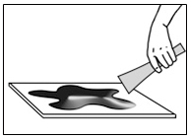

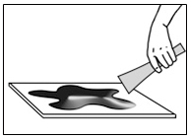

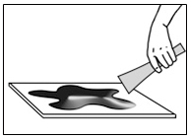

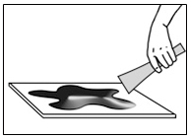

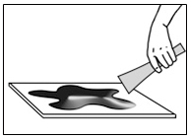

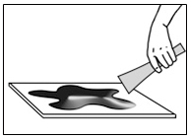

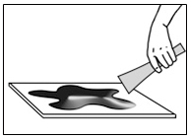

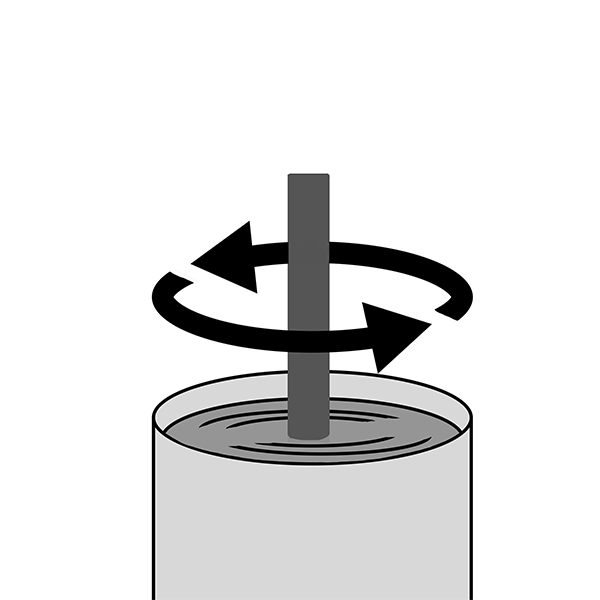

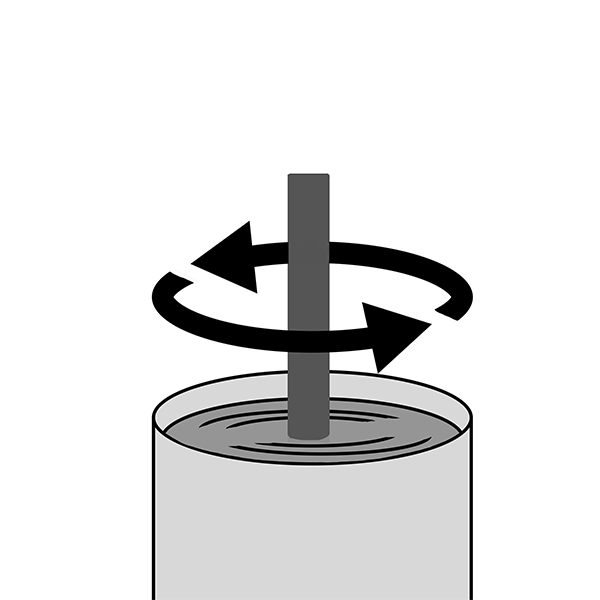

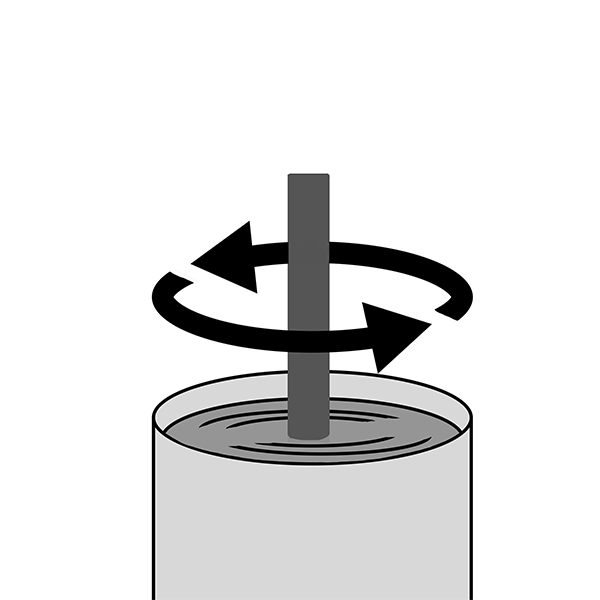

OIL SPILL DISPERSANT

SEALXPERT OIL SPILL DISPERSANT

FEATURES:

- Converts oil spills to hydrophilic droplets that are easily biodegradable

- Does not contribute further to pollution

- Easy to handle and apply

- Applicable to mineral oils, crude oils, fuel oils, kerosene, white spirit and lubricant oils

APPLICATION:

- Can be applied to oil slicks either by aircraft or by ships with spraying equipment

- Used by injection below water to break up oil before it reaches the surface

- Can be used as a tank cleaner for the removal of heavy oil contaminations like crude oil, paraffines etc.

SEALXPERT OIL SPILL DISPERSANT

PACKAGE:

- 18 litres

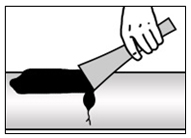

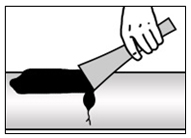

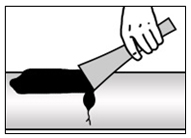

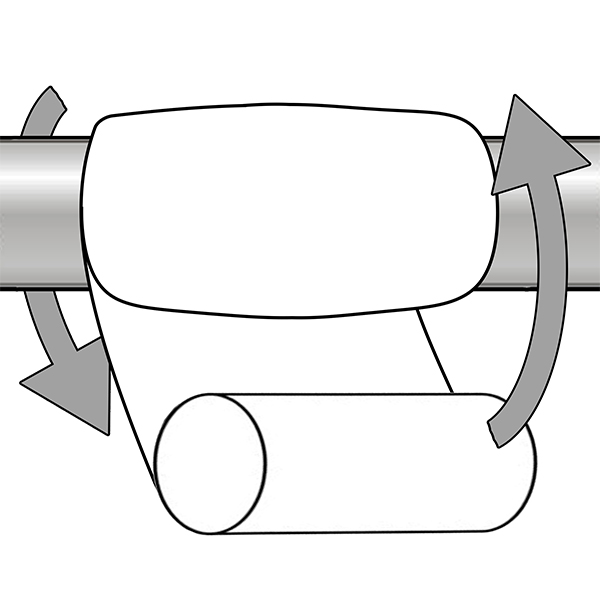

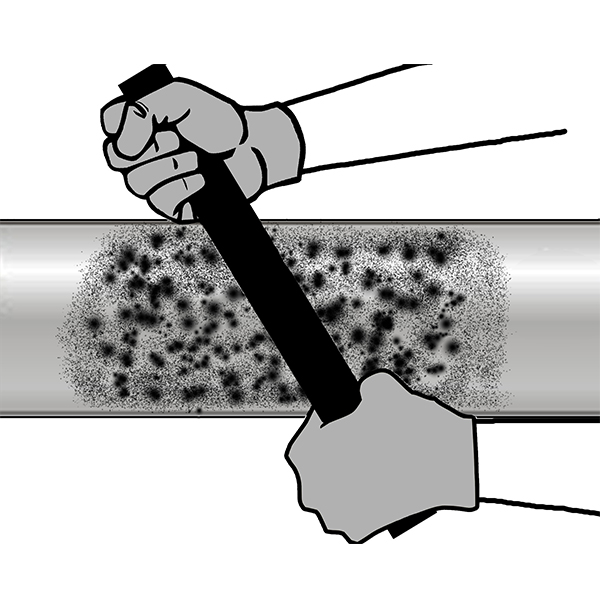

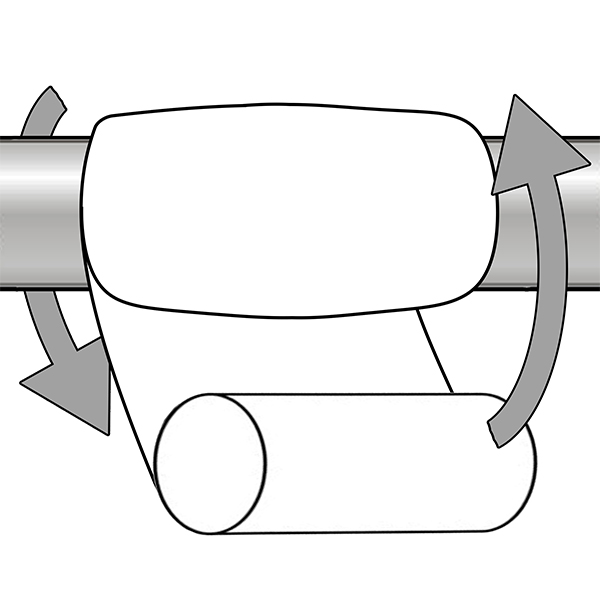

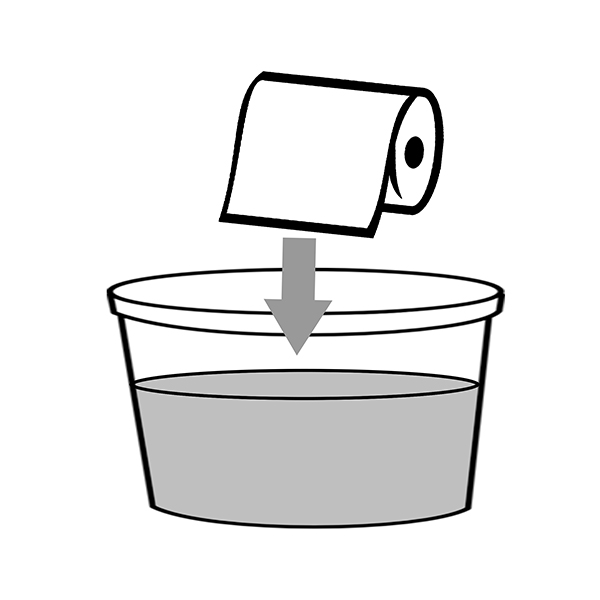

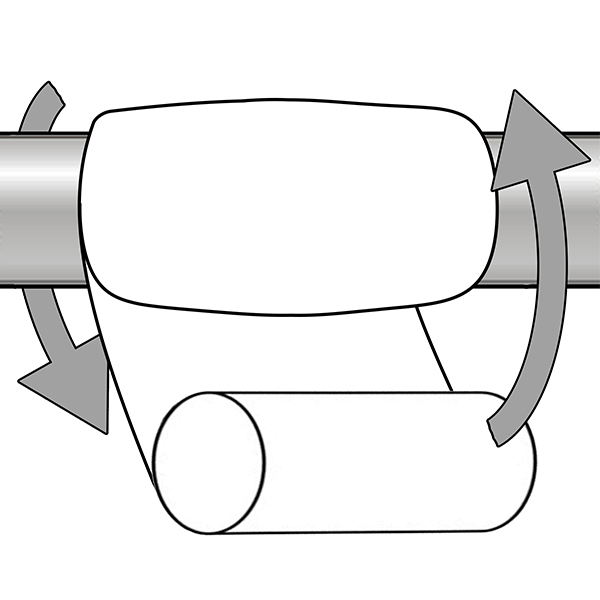

AIR COOLER CLEANER

SEALXPERT AIR COOLER CLEANER

FEATURES:

- Penetrates and softens the stubborn carbon deposits

- Efficient and economical

- Leaves no residue and has no harmful effect on engine

- Safe to use on most metals

- Acts quickly and thoroughly

- Easy to apply

- Non corrosive

APPLICATION:

- Suitable for all types of diesel engines

- Removes oil, grease and carbon deposits from marine engines, air coolers, scavenging systems and turbochargers

- Can be used for light carbon removal from machinery parts

SEALXPERT AIR COOLER CLEANER

PACKAGE:

- 18 litres

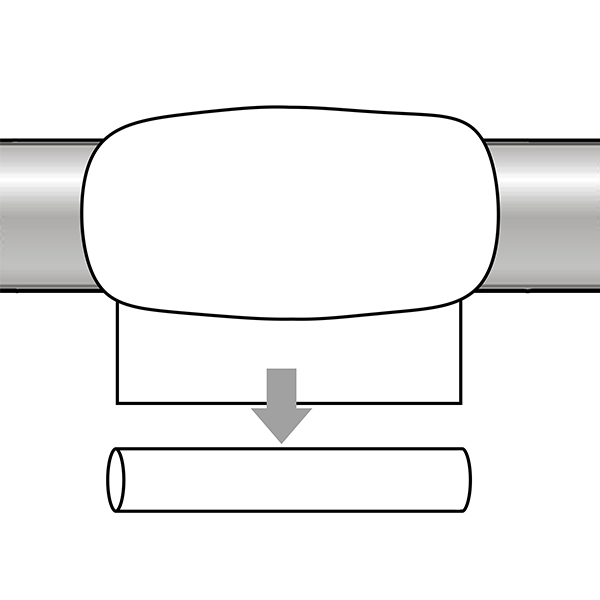

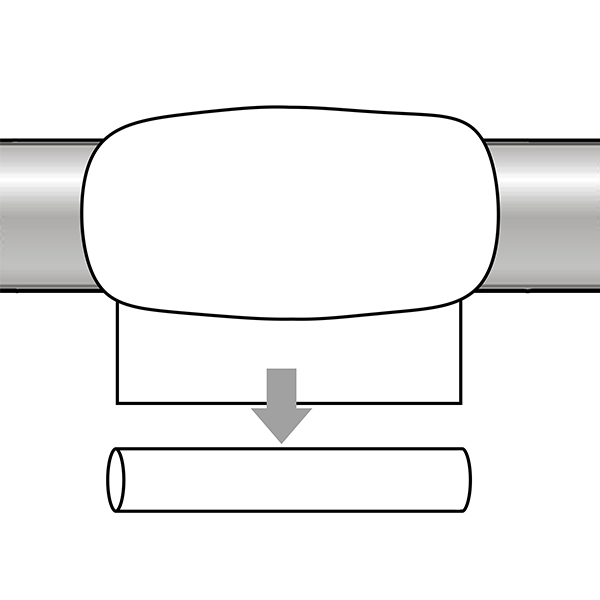

HEAVY DUTY ALKALI CLEANER

SEALXPERT HEAVY DUTY ALKALI CLEANER

FEATURES:

- Fast cleaning results

- Low dosage

- Cost effective

- Completely safe on epoxy coatings

APPLICATION:

- Removal of natural oils and fats

- Cleaning after wax deposits

- Removal of soot deposits from inert gas systems

- Can be used for deodorizing, gas and hydrocarbon freeing of tanks

SEALXPERT HEAVY DUTY ALKALI CLEANER

PACKAGE:

- 20 litres

CLEANER & DEGREASER

SEALXPERT CLEANER & DEGREASER

FEATURES:

- Quickly removes stubborn grease

- Designed to dissolve tough, baked-on grease from stainless steel and countertops

- Leaves stainless steel shiny and streak free — no stickiness or residue

- Can be diluted into spray bottle or bucket

APPLICATION:

- Countertops, stovetops, work surfaces, stainless steel equipment, walls, splash guards, oven exteriors, broiler pans, plastics, glass, kitchen equipment and fiberglass reinforced plastic.

SEALXPERT CLEANER & DEGREASER

PACKAGE:

- 5 litres / 18 litres

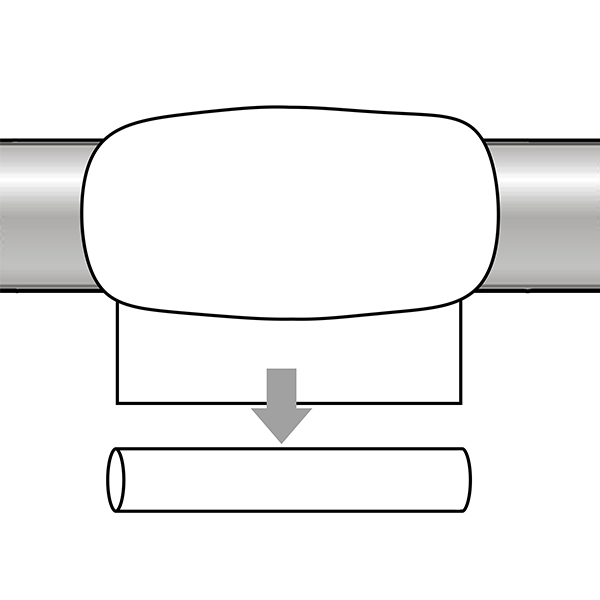

PICKLING & PASSIVATION GEL

SEALXPERT PICKLING & PASSIVATION GEL

FEATURES:

- Fast-acting and simple to use

- stain-free and does not impart yellow or black stains after washing with water

APPLICATION:

- Removes weld scale, black oxides and discoloration from the surface of stainless steel

- Gives stainless steel surfaces a protective surface to resist corrosion

SEALXPERT PICKLING & PASSIVATION GEL

PACKAGE:

- 1 kg

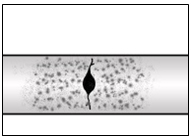

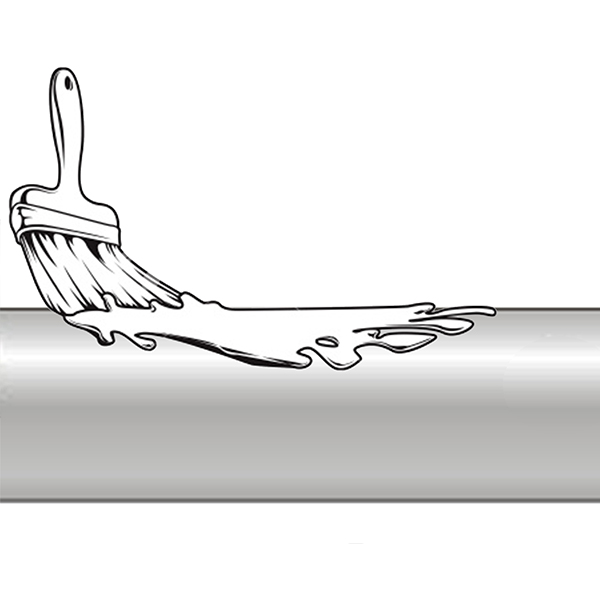

RUST CONVERTER

SEALXPERT RUST CONVERTER

FEATURES:

- Solvent free

- Does not contain nonylphenol ethoxylates or other estrogenic compounds

- Economical in use

- Non-flammable

- Odourless

APPLICATION:

- Used on rusted galvanised roofs or surfaces, ornamental ironwork, fencing, structural steel, automotive panels, rusted nuts and bolts and hand tools.

SEALXPERT RUST CONVERTER

PACKAGE:

- 4 litres

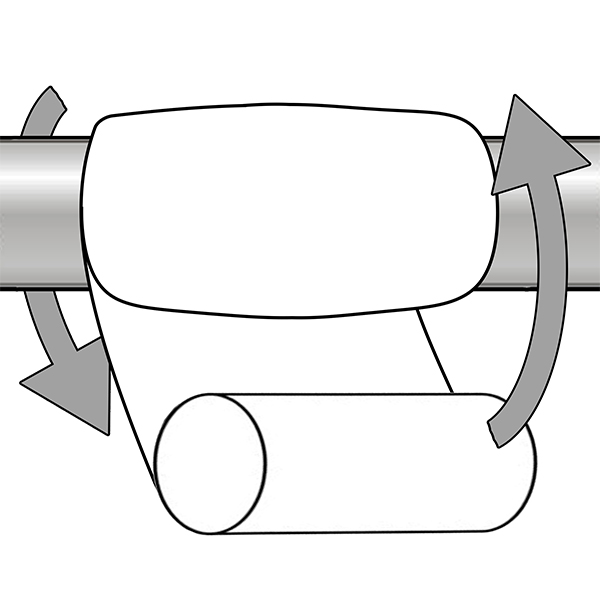

RUST REMOVER

SEALXPERT RUST REMOVER

FEATURES:

- Safe on all metals and most plastics

- Removes the rust and prevents rust formation

- Acts as a rust remover and passivator

APPLICATION:

- Used for removal of rust from metals like structural steel, rib bar, nail, refinery, railway, metal fabrication, and maintenance work shop etc.

SEALXPERT RUST REMOVER

PACKAGE:

- 25 litres

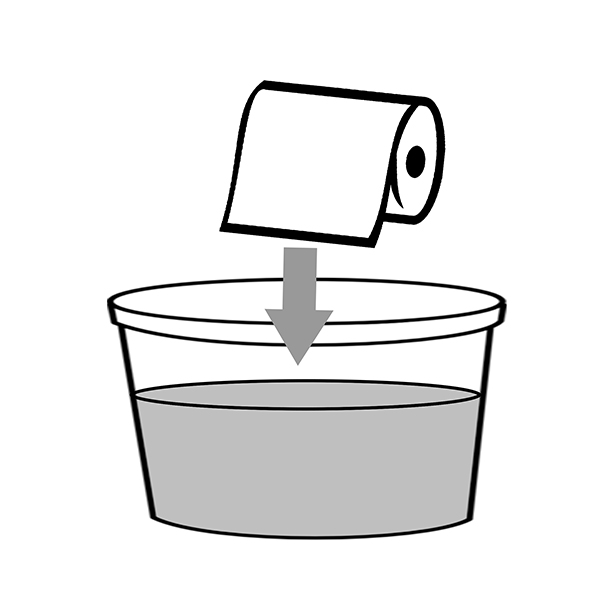

HAND SANITIZER TOWELS

SEALXPERT HAND SANITIZER TOWELS

FEATURES:

- 70% Isopropyl Alcohol

- Non-aromatic

- Medical grad

- Thoroughly clean dirt and grease

- Quickly emulsifies grease

APPLICATION:

- Eliminating 99% of germs and bacterial

- Effective for removal of epoxy and polyester resins

SEALXPERT HAND SANITIZER TOWELS

PACKAGE:

- 80 sheets

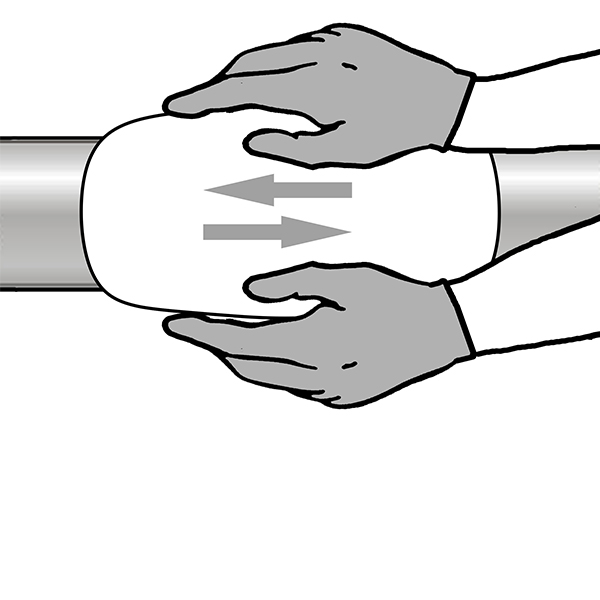

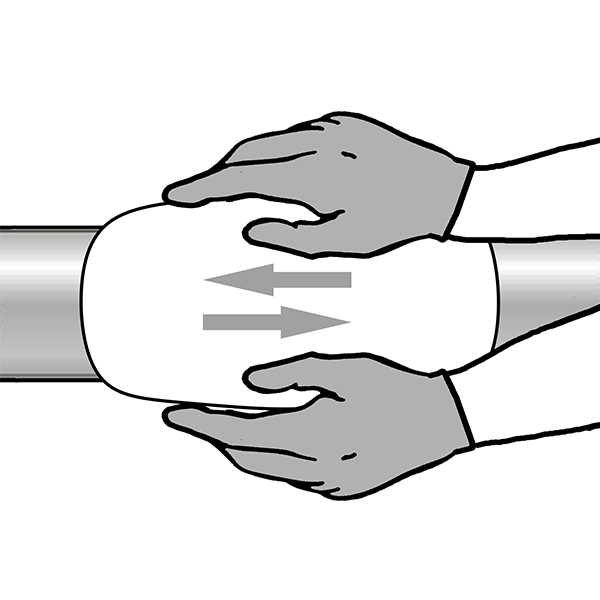

HAND CLEANING TOWELS

SEALXPERT HAND CLEANING TOWELS

FEATURES:

- Most versatile cleaning towel

- Won’t dry easily

- Thoroughly clean dirt and grease

- Quickly emulsifies grease

APPLICATION:

- Effective for removal of epoxy and polyester resins

- Takes off grease, tar, printer’s inks and many other difficult to remove substances.

SEALXPERT HAND CLEANING TOWELS

PACKAGE:

- 80 sheets

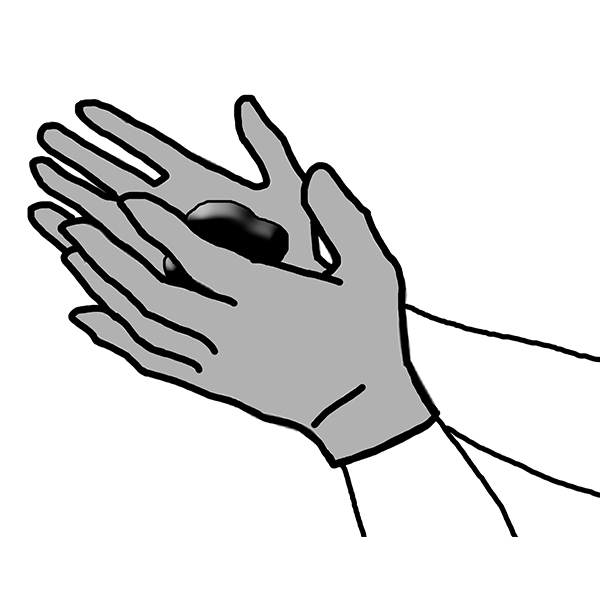

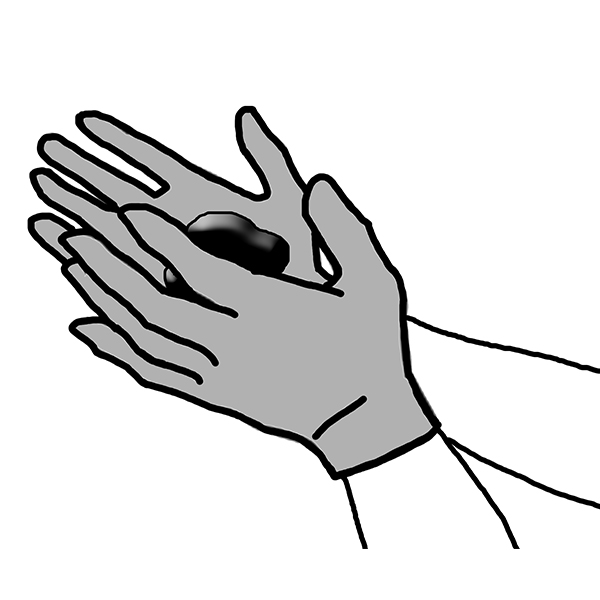

PUMICE HAND CLEANER

SEALXPERT PUMICE HAND CLEANER

FEATURES:

- Containing no petroleum solvents

- Thoroughly clean dirt and grease

- Quickly emulsifies grease

- Mild soap designed for industrial use

APPLICATION:

- Removes oils, grease, grime, fresh paint, tar, soot and all kinds of industrial dirt from hands.

SEALXPERT PUMICE HAND CLEANER

PACKAGE:

- 4 litres

ANTISEPTIC HAND GEL

SEALXPERT ANTISEPTIC HAND GEL

FEATURES:

- Mild antiseptic properties

- Thoroughly clean dirt and grease

- Quickly emulsifies grease

- Mild soap designed for industrial use

APPLICATION:

- Removes oils, grease, grime, fresh paint, tar, soot and all kinds of industrial dirt from hands.

SEALXPERT ANTISEPTIC HAND GEL

PACKAGE:

- 1 kg / 4 kg

ELECTRICAL CONTACT GREASE

SEALXPERT ELECTRICAL CONTACT GREASE

FEATURES:

- Increase reliability & longevity of connections

- Excellent conductivity

- Long-term protection against corrosion and wear

APPLICATION:

- Suitable for use with all materials used in the manufacture of electrical contacts and switch gear

- Ideal for applications in the automotive, rail, and electrical industries

- Particularly suited for the lubrication of copper alloy electrical contacts in an environment where plastic casings, housings or other plastic parts are present

- Conductive moving parts, switches, control valve pins, terminals, voltage regulators, etc.

SEALXPERT ELECTRICAL CONTACT GREASE

PACKAGE:

- 500 gram / 2.5 kg / 15 kg

LOW TEMPRATURE GREASE

SEALXPERT LOW TEMPRATURE GREASE

FEATURES:

- Water and steam resistant

- Provide excellent lubrication performances at low temperatures

- High oxidation stability

- Protects against corrosion

APPLICATION:

- Designed for low temperature freezer and cold storage applications

- Low temperature automotive applications

- For large low-speed rolling bearings subjected to high loads

- Ideal lubricant for spherical roller bearings in roller presses, bowl mill, rotary crushers and also suitable for plain bearings

SEALXPERT LOW TEMPRATURE GREASE

PACKAGE:

- 13 kg

EXTREME PRESSURE GREASE

SEALXPERT EXTREME PRESSURE GREASE

FEATURES:

- Outstanding load carrying capacity

- Superior mechanical stability

- Excellent resistance to water wash-out

- Oxidation stability

- Excellent corrosion protection

APPLICATION:

- Heavy duty bearings served by centralised dispensing equipment

- Extreme-pressure gear grease for applications at normal ambient temperature

- Heavy duty bearings and general industrial lubrication

- Heavy duty plain and rolling element bearings operating under harsh conditions including shock loading in wet environments

SEALXPERT EXTREME PRESSURE GREASE

PACKAGE:

- 13 kg

- #0 / #1 / #3

MULTI-PURPOSE GREASE

SEALXPERT MULTI-PURPOSE GREASE

FEATURES:

- Reliable high temperature performance

- Good oxidation and mechanical stability

- Excellent corrosion resistance

- Long storage life and low noise

APPLICATION:

- Used under a wide range of operating conditions, including severe duty, elevated temperatures and in the presence of moisture

- Rolling element and plain grease lubricated bearings

- Electric motor bearings

SEALXPERT MULTI-PURPOSE GREASE

PACKAGE:

- 13 kg

- #1 / #2 / #3

MACHINE CUTTING OIL

SEALXPERT MACHINE CUTTING OIL

FEATURES:

- Inhibits corrosion and staining

- Improves surface finish

- Increases tool life

- Excellent cooling properties

- Extreme Pressure Resistant

APPLICATION:

- Suitable for all removal and grinding operations

- Extend tool life to keep metalworking and machining processes running smoothly

SEALXPERT MACHINE CUTTING OIL

PACKAGE:

- 4 litres

PENETRATING OIL

SEALXPERT PENETRATING OIL

FEATURES:

- Easy penetration

- Loosens rust, oil, grease

- Rust protection

- Displaces water / moisture

- Non-corrosive

- Non-conductive

- Lubrication

- Not harmful to paint or metals

- Low surface tension to replace moisture

APPLICATION:

- Used to loosen up rust and hardened oil and grease from nuts, bolts, shackles, etc. and for lubrication

- Intended for used wires to remove rust and old oil and grease before applying a new coating.

SEALXPERT PENETRATING OIL

PACKAGE:

- 4 litres

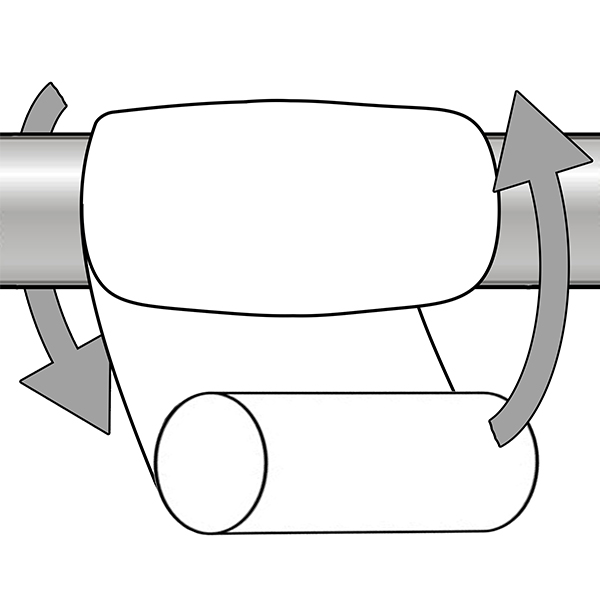

OPEN GEAR & WIRE ROPE GREASE

SEALXPERT OPEN GEAR & WIRE ROPE GREASE

FEATURES:

- High pressure resistance

- High wear protection

- Extremely adhesive

- Resistance against water

APPLICATION:

- Emergency lubrication

- Used for initial lubrication of chains with hollow pins equipped with grease nipples

- Also used for gear drives and open gears, sliding bearings operating at low speeds and high temperatures

SEALXPERT OPEN GEAR & WIRE ROPE GREASE

PACKAGE:

- 2.5 kg / 15 kg

HI-SPEED MOLY GREASE

SEALXPERT HI-SPEED MOLY GREASE

FEATURES:

- Low viscosity ester oil base, which has outstanding low torque and low friction properties.

- Exceptional lubricity lasts for long periods of time over a wide range of temperatures

APPLICATION:

- Use on bearings in electric machinery designed to reduce energy and current usage

- Use on high speed conveyance linear motion devices and ball screws.

- Use on machine tool spindles and other bearings that revolve at high-speeds.

SEALXPERT HI-SPEED MOLY GREASE

PACKAGE:

- 2.5 kg / 15 kg

HI-TEMP MOLY GREASE

SEALXPERT HI-TEMP MOLY GREASE

FEATURES:

- Containing heat-resistant molybdenum disulphide (MoS2) and graphite, in various combinations.

- Reduce seizure even at high temperatures applications

APPLICATION:

- Suited to extreme high temperatures required at ironworks, cement plants, etc. for sliding; rotating and threaded parts in steel mill sliding nozzles and rotary nozzles, Bearings in ladle hangers and furnace dampers; transfer surfaces of tire liners and support rollers in rotary kilns at cement plants; sliding parts, bolts, nuts, pins, and bushings under high temp.

SEALXPERT HI-TEMP MOLY GREASE

PACKAGE:

- 2.5 kg / 15 kg

MOLY GREASE

SEALXPERT MOLY GREASE

FEATURES:

- Lithium soap greases have excellent water resistance and shear stability

- Versatile greases recommended for general and wide applications.

APPLICATION:

- Suited to a wide range of applications, including bearings, gears, and sliding parts.

SEALXPERT MOLY GREASE

PACKAGE:

- 500 gram / 2.5 kg / 15 kg

111 SILICONE COMPOUND

SEALXPERT 111 SILICONE COMPOUND

FEATURES:

- Excellent for high temperature bearings, conveyor systems, and low-temp refrigeration systems

- Water resistant

- Non-toxic

- Extremely chemical resistant

- Translucent paste

- Highly resistant to oxidation and shear breakdown

- Suitable for valve lubrication

- Low vapor pressure

- Low volatility

- High dielectric strength

APPLICATION:

- Lubrication for control and pressure plug valves, water softener and faucet valves

- Sealant for vacuum and pressure systems

- Sealant for outdoor equipment (also shipboard) subject to washing and harsh environmental exposure: meters, electrical service entrance and underground connections

- Damping medium for dash pots in electrical and electronic equipment

- For subzero processing facilities and spiral freezer applications

- Rubber and plastic O-rings, gaskets and seals

- Chemical barrier coating

SEALXPERT 111 SILICONE COMPOUND

![]()

PACKAGE:

- 500 gram / 1 kg

111 SILICONE GREASE LOW TEMPERATURE

SEALXPERT 111 SILICONE GREASE LOW TEMPERATURE

FEATURES:

- Oxidisation resistance

- Non-corrosive

- Water washout resistance

- Good lubricity

- Chemically inactive

APPLICATION:

- Suited for low temperature lubrication, and provides resistance to oxidization and washout

- Lubricant for dynamic pneumatic o-rings

- As a seal between rubber and metal parts

- Lubrication for motors, pump, bearings, valves, gears, and seals

SEALXPERT 111 SILICONE GREASE LOW TEMPERATURE

![]()

PACKAGE:

- 1 kg

111 SILICONE GREASE

SEALXPERT 111 SILICONE GREASE

FEATURES:

- Non-toxic, stiff silicone compound.

- Strong adhesion, non-melting and maintains consistency over wide temperature range.

- Resistant to many chemicals and gases.

- Low evaporation rate.

APPLICATION:

- Long-term lubrication of valves, stop cocks, plug cocks, ‘O’ rings, valve/lip seals, packings, gaskets.

- Suitable for some vacuum and pressure systems.

SEALXPERT 111 SILICONE GREASE

![]()

PACKAGE:

- 500 gram / 1 kg

MOLY M-30 LIQUID DISPERSION

SEALXPERT MOLY M-30 LIQUID DISPERSION

FEATURES:

- Increases load-carrying capacity, reduces friction, wear and noise.

- Lowers oil operating temperatures and stops gear pitting.

- Solid lubricant particles are small enough to pass through all common filter types.

APPLICATION:

- Recommended as an additive to mineral-based lubricating, engine and gear oils in circulating and splash lubrication system and gearboxes.

SEALXPERT MOLY M-30 LIQUID DISPERSION

PACKAGE:

- 1 litre

MOLY M LIQUID DISPERSION

SEALXPERT MOLY M LIQUID DISPERSION

FEATURES:

- Increases load-carrying capacity, reduces friction, wear and noise.

- lowers oil operating temperatures and stops gear pitting.

- Solid lubricant particles are small enough to pass through all common filter types.

APPLICATION:

- Recommended as an additive to mineral-based lubricating, engine and gear oils in circulating and splash lubrication system and gearboxes.

SEALXPERT MOLY M LIQUID DISPERSION

PACKAGE:

- 5 litres

MOLY GN PASTE

SEALXPERT MOLY GN PASTE

FEATURES:

- High pressure-absorption capacity

- Low coefficient of friction

- Prevents frictional corrosion and scoring

- Protection from stick-slip

- Good anti-corrosion properties

- Reduces frictional corrosion

- Simplifies dismantling processes

- High surface covering capacity

APPLICATION:

- Press-fit production of all types of machine elements, as a running-in lubricant for new machines and gearboxes

- Permanent lubrication of machine elements that are moved only rarely or slightly and also for drilling, sawing and thread cutting

- Used successfully for lubricating threaded spindles, splined shafts, toothed gears, worm and transmission gears, screws, valves, pumps, machine tool guides and also for the tightening and fitting of roller bearings, washers, wheels, flanges and bolts.

TECHNICAL DATA:

| Property | Value |

| Colour | Black |

| Unworked Penetration | 280-310 mm/10 |

| Density at 20 °C | 1.35 g/cm³ |

| Service Temperature | -25 °C to 450 °C (-13 °F to 842 °F) |

SEALXPERT MOLY GN PASTE

PACKAGE:

- 500 gram/can

MOLY M77 PASTE

SEALXPERT MOLY M77 PASTE

FEATURES:

- Paste lubrication up to 230°C (446°F), dry lubrication up to 400°C (662°F)

- Good water resistance

- Good volatilization properties

- Compatible with many types of elastomers and plastics (test for compatibility)

APPLICATION:

- Suitable for lubrication points with low to moderate loads and low speeds which are subjected to water and extreme temperatures

- Suitable for lubricating parts consisting of materials that are not resistant to mineral oils

- Used successfully on metal/metal combinations with frictional and contact surfaces, brake anchor plates and the brake pistons of disc brakes

TECHNICAL DATA:

| Property | Value |

| Colour | Black-grey |

| Unworked Penetration | 280-330 mm/10 |

| Density at 20 °C | 1.95 g/cm³ |

| Service Temperature (Paste-like) | -45 °C to 230 °C (-49 °F to 446 °F) |

SEALXPERT MOLY M77 PASTE

PACKAGE:

- 500 gram/can

ALUMINIUM ANTI-SEIZE COMPOUND

SEALXPERT ALUMINIUM ANTI-SEIZE COMPOUND

FEATURES:

- Aluminium based anti-seize compound

- High Oxidation resistance

- Provides rust protection and reduces fretting corrosion

- Good resistance against both fresh water and seawater, suitable for marine use

APPLICATION:

- Provides long term protection under the toughest exposure and temperature conditions to prevent wear, corrosion, rust and seizure.

- Use on all studs, nuts, bolts and other threaded connections, including turbine casing studs, burner nozzles, all boiler inspection points and furnace bolts.

- Ideal for applications where the presence of copper is not desirable due to the risk of electrolytic corrosion, or in the presence of chemicals which react with copper

SEALXPERT ALUMINIUM ANTI-SEIZE COMPOUND

PACKAGE:

- 500 gram/can

NICKEL ANTI-SEIZE COMPOUND

SEALXPERT NICKEL ANTI-SEIZE COMPOUND

FEATURES:

- Contains nickel, aluminium and graphite in a non-melt base

- Contains corrosion and oxidation inhibitors

- Resistant to acids and ammonia

- Recommended for use when copper cannot be present

APPLICATION:

- Use on threaded parts, bushings, gears, valve systems, chain sprockets, levers, hinges, pivots, rollers, heat exchanger or manifold bolts

- Also used as a gasket release agent

- Electrically conductive, protects up to 1350°C (2462°F)

- Recommended for use with stainless steel screws, flanges, nozzles, couplings and other metal fittings

- Also used where high Nickel alloy materials such as stainless steel, or where Titanium or other hard metals are involved.

SEALXPERT NICKEL ANTI-SEIZE COMPOUND

PACKAGE:

- 500 gram/can

COPPER ANTI-SEIZE COMPOUND

SEALXPERT COPPER ANTI-SEIZE COMPOUND

FEATURES:

- Highly effective oxidation inhibitors

- Resistant to corrosion and vibration

- Resistant to contraction and expansion

- Ensures rapid and easy assembly of threaded parts

- Prevents seizing and galling

- Reduces wear in areas of high friction

- Withstands temperature from -40°C to 1100°C (-35°F to 2000°F)

APPLICATION:

- Ensures quick and trouble-free dismantling for routine maintenance even after prolonged exposure to high temperature areas up to 1100°C (2000°F) or in corrosive conditions such as coal mining or marine environments

- Extensively used on tool joints, drill collars, precision threads, large and small diameter pipelines and valves

TECHNICAL DATA:

| Property | Value |

| Colour | Copper |

| Operating Temperature Range | -40 °C to 1100 °C (-40 °F to 2000 °F) |

| Solidifying Temperature | -18 °C (0 ºF) |

| Unworked Penetration at 25 °C | 310–340 mm/10 |

SEALXPERT COPPER ANTI-SEIZE COMPOUND

PACKAGE:

- 500 gram/can

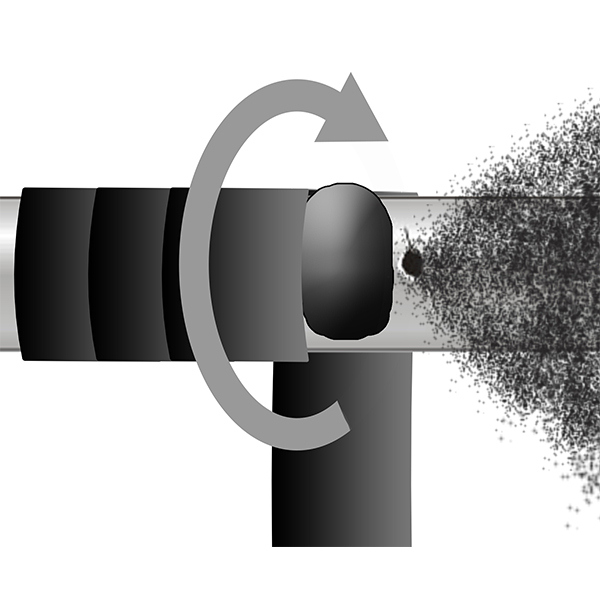

MOLY G-RAPID

SP50 MOLY G-RAPID

FEATURES:

- Designed to be running-in lubricant

- Does not require burnishing

- Quickly evaporates and allow sprayed parts to be used within seconds

- Has a high service temperature

APPLICATION:

- Seizure prevention during machine assembly such as press or heat-fitting.

- Seizure prevention and run-in protection for motor axles, splines, and cams

- Protects against overheating of power screws and packing seals

- Lubrication during metal working such as thread cutting, grinding and casting

- Pre-treatment of surfaces before grease or oil lubrication

- Fretting corrosion prevention in the fitting area of machine parts

SP50 MOLY G-RAPID

PACKAGE:

- 500 ml/can

MOLY M1000 ANTI-SEIZE COMPOUND

SEALXPERT MOLY M1000 ANTI-SEIZE COMPOUND

FEATURES:

- Can be used over a wide range of temperature

- High load-carrying capacity

- Enables non-destructive dismantling, even after long use at high temperatures

- Coefficient of friction unchanged in the area of oiled bolts, even after several bolt re-tightening and loosening processes

- Good corrosion protection

APPLICATION:

- Suitable for bolted joints that are subjected to high temperatures up to 650°C (1202°F) and to corrosive effects, and which, after assembling and the initial operation, have to be re-tightened or disconnected. In order to ensure constant pre-stressing forces, uniform and steady coefficients of friction of the lubricant are necessary

- Used successfully for cylinder head bolts, nozzle head screws of plastic injection moulding machines, bolted joints in the chemical industry, and also for the tension rings of centrifuges

TECHNICAL DATA:

| Property | Value |

| Colour | Brown |

| Unworked Penetration | 280-310 mm/10 |

| Density at 20 °C | 1.26 g/cm³ |

| Service Temperature | -30 °C to 650 °C (-22 °F to 1202 °F) |

SEALXPERT MOLY M1000 ANTI-SEIZE COMPOUND

PACKAGE:

- 1 kg/can

MOLY MICRO POWDER

SEALXPERT MOLY MICRO POWDER

FEATURES:

- Excellent lubricating properties

- Reduction of friction and wear

- Resistant to oxidation

- Extreme pressure resistance

- Wide service temperature range

APPLICATION:

- Lubricate metal surfaces of all kinds in many difficult and extreme environments

- Metal/metal pairings at extreme loads and slow speeds

- Metal/plastic pairings at low loads and low to medium speeds

TECHNICAL DATA:

| Property | Value |

| Colour | Blackish |

| Purity (MoS₂ content) | 98% |

| Particle Size | 3 – 4 μm |

| Service Temperature Range | -185 °C to 450 °C (-301 °F to 842 °F) |

SEALXPERT MOLY MICRO POWDER

PACKAGE:

- 500 gram/can

MOLY Z POWDER

SEALXPERT MOLY Z POWDER

FEATURES:

- Excellent lubricating properties

- Reduction of friction and wear

- Resistant to oxidation

- Extreme pressure resistance

- Wide service temperature range

APPLICATION:

- Used for applications that are exposed to extreme environments, slow speeds, and heavy loads

- Used on self-lubricating plastics, metallic surfaces, metal working compounds, brake linings, press fittings, and as a run-in aid

TECHNICAL DATA:

| Property | Value |

| Colour | Blackish |

| Purity (MoS₂ content) | 98% |

| Particle Size | 3 – 4 μm |

| Service Temperature Range | -185 °C to 450 °C (-301 °F to 842 °F) |

SEALXPERT MOLY Z POWDER

PACKAGE:

- 1 kg/can

SMOKE DETECTOR TESTER

AEROSOL PRODUCTS

SMOKE DETECTOR TESTER

FEATURES:

- Easy to use

- Evaporates without leaving residues

APPLICATION:

- For functional testing of smoke detectors

- Works with both photoelectric and ionization smoke detectors

SEALXPERT SMOKE DETECTOR TESTER

PACKAGE:

- 450 ml/can

STAINLESS STEEL POLISH

AEROSOL PRODUCTS

STAINLESS STEEL POLISH

FEATURES:

- Leaves a clean, smear free, polished surface

- Leaves no residue

APPLICATION:

- Removes streaks, smudges and fingerprint

- Prevents rust, corrosion and dis coloration

- Suitable for use on stainless steel, chrome, architectural aluminium, and other interior metal surfaces

- For elevators, escalators, dishwashers, refrigerators, windows, etc.

SP80 STAINLESS STEEL POLISH

PACKAGE:

- 450 ml/can

VARNISHCOTE CLEAR / VARNISHCOTE RED

AEROSOL PRODUCTS

VARNISHCOTE CLEAR / VARNISHCOTE RED

FEATURES:

- Smooth brush-free finish on natural, stained or painted wood

- Dries in minutes

- Easy to use

APPLICATION:

- Protect printed circuit boards against creepage and short circuits

- Protecting components from condensation and moisture

- Insulates cables and wires

- Electrical contacts lubrication

- Coating terminal strips, screw connections, and switch boxes that are exposed to atmospheric effects

SP70C VARNISHCOTE CLEAR / SP70R VARNISHCOTE RED

PACKAGE:

- 450 ml/can

SILICONE GREASE SPRAY

AEROSOL PRODUCTS

SILICONE GREASE SPRAY

FEATURES:

- Seals, lubricates, protects, insulates and waterproofs

- Safe on most rubber and plastics

- Chemical, oil and water resistant

- Temperature resistant

APPLICATION:

- O-Rings lubrication

- Spark plugs lubrication

- Battery terminals lubrication

- Electrical contacts lubrication

- Gasket lubrication

- Plastics and rubber component lubrication

SP60 SILICONE GREASE SPRAY

![]()

PACKAGE:

- 450 ml/can

MOLY G-RAPID SPRAY

AEROSOL PRODUCTS

MOLY G-RAPID SPRAY

FEATURES:

- Designed to be running-in lubricant

- Does not require burnishing

- Quickly evaporates and allow sprayed parts to be used within seconds

- Has a high service temperature

APPLICATION:

- Seizure prevention during machine assembly

- Seizure prevention and run-in protection for motor axles, splines and cams

- Power screw and packing seals

- Lubrication during metal working

- Pre-treatment of surfaces

SP50 MOLY G-RAPID SPRAY

PACKAGE:

- 500 ml/can

MULTI-PURPOSE LUBRICANT

AEROSOL PRODUCTS

MULTI-PURPOSE LUBRICANT

FEATURES:

- Stops squeaks

- Loosen rusty, frozen and sticky parts

- Protects against rust and metal corrosion

- Removes moisture

APPLICATION:

- General and multi-purpose lubricating spray for all machine static and rotating parts and components

SP40 MULTI-PURPOSE LUBRICANT

PACKAGE:

- 450 ml/can

ZINC COLD-GALVANIZING SPRAY (BRIGHT)

AEROSOL PRODUCT

ZINC COLD-GALVANIZING SPRAY (BRIGHT)

What is Galvanizing?

Galvanizing is the process of applying a protective zinc coating to steel or iron to provide protection and prevent corrosion. When exposed to the atmosphere, iron reacts with the presence of oxygen and thus becomes oxidized, which is how iron corrodes. The galvanized layer creates a zinc barrier and sacrificial cathodic protection that prevent the above reactions from occurring.Like all metals, zinc corrodes when exposed to air and moisture. However, zinc corrodes approximately 100 times slower than other metals. When zinc reacts with oxygen, a thin layer of zinc oxide is formed. When this zinc oxide reacts with water, zinc hydroxide is formed. This zinc hydroxide further reacts with carbon dioxide to produce a thin layer of zinc carbonate. This zinc carbonate will then adhere to the zinc coating for better corrosion protection. Zinc carbonate is resilient, chemically stable, adheres firmly to metal surfaces, and acts as a protective barrier, preventing air and moisture from contacting the underlying substrate and preventing further corrosion and deterioration.

What is a Zinc Galvanizing Spray?

Zinc galvanizing spray is a sprayable, fast-curing zinc powder anticorrosive primer in an aerosol. It forms a fast-drying, adherent protective layer to repair damaged galvanic surfaces and to protect the entire exhaust system. The application of zinc galvanizing spray can be carried out in the galvanizer’s plant or on the job site. Zinc galvanizing spray is used as an anti-rust and anti-corrosion protection for iron and steel surfaces, especially at welding seams. It can be used as a coating for welding joints and drilling holes, as a conductive intermediate layer for spot welding and wherever metal must be protected from corrosion. Zinc galvanizing spray is also used in steel structure engineering, equipment, machinery, ships and appliances manufacturing.

FEATURES:

- High zinc content

- High adhesion strength on surfaces

- Protective zinc surface coating

APPLICATION:

- Repair damaged galvanizing surfaces

- Alternative to hot-dip galvanizing

- Can be applied over bare steel surfaces and weld

- Used as finished coat

Why Choose our Zinc Galvanizing Spray?

SealXpert SP30 Zinc Cold-Galvanizing Spray (Bright) is a zinc rich compound (95% enriched zinc content) that ideal for repairing damaged galvanized surfaces. It can be applied as an alternative if hot-dip galvanizing is not available. SealXpert zinc galvanizing spray can act as a finish coat on clean iron, steel and their welds.SealXpert zinc galvanizing spray has excellent adhesion properties and is easy to apply. Aside from that, it also provides long-term corrosion protection, helps to prevent rust and corrosion of metal surfaces.

SealXpert zinc galvanizing spray has a wide range of applications, such as welded seams, spot welding repairs, rivet holes, signs and signposts, pipes, roofs, water tanks, boats and etc.

Why is Zinc Used in Galvanizing Spray?

Zinc is used as a sacrificial agent to protect metals (steel and iron) from corrosion. This is because zinc is more susceptible to oxidation and acid corrosion than steel, so zinc takes the brunt of the damage rather than steel. The zinc layer sacrifices itself and provides anodic protection to the surface of the metal (steel or iron) exposed to the atmosphere due to scratches. Zinc will corrode first, so any damaging acid will be stopped before it can corrode the underlying steel. Zinc has therefore become an important element in galvanized structures today, protecting them from long-term corrosive damage and extending their service life considerably.

Why Zinc and not Copper?

Galvanizing spray uses zinc because it costs less than copper and is more cost-effective. In addition, zinc does not react with other metals as readily as copper, so there is less surface discoloration after zinc galvanizing. Another advantage is that zinc provides better corrosion protection than copper, making it a more reliable choice in some situations. This makes zinc galvanizing spray especially useful in areas where salt water or severe weather can cause damage to metal objects.

SP30 ZINC COLD-GALVANIZING SPRAY(BRIGHT)

PACKAGE:

- 450 ml/can

CLEANER AND DEGREASER

AEROSOL PRODUCTS

CLEANER AND DEGREASER

WHAT IS A CLEANER AND DEGREASER?

Cleaner and degreaser is a chemical product designed to remove grease, oils, cutting fluids, and other heavy contamination. It quickly breaks through tough grease and dirt.The most commonly used cleaner and degreaser is water-based and solvent-based. Water-based cleaner and degreaser will create a ‘lift’ in the grease, causing it to float on the water and produce residues, which can then be removed by a variety of separation techniques. Solvent-based cleaner and degreaser designed to cause chemical reactions to change the state of the substance and make it easier to remove.

FEATURES:

- Heavy duty evaporating cleaner and degreaser.

- Specially formulated for diverse surface cleaning.

- Remove pitch ta, adhesives, heavy oil stains.

- Form a glossy clear layer to protect surface.

- Applicable for various machine parts

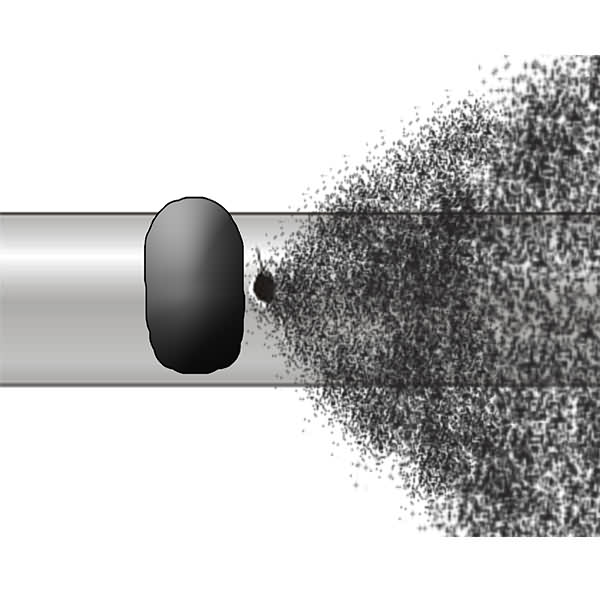

APPLICATION:

- Cleans low-voltage electric motors

- Cleans heavy duty equipment while in operation

WHY CHOOSE OUR CLEANER AND DEGREASER?

SealXpert SP20 Cleaner and Degreaser is heavy-duty evaporating cleaner and degreaser for use on electric motors and other heavy-duty electrical and mechanical equipment. It minimises downtime by cleaning low voltage motors and equipment while in operation.SealXpert SP20 Cleaner and Degreaser is non-conductive, non-corrosive, and quickly penetrates into hard-to-reach areas.SealXpert SP20 Cleaner and Degreaser has a wide range of applications, such as industrial equipment and machinery, mechanical and electrical parts, auto parts and engines, cables and wires, electric motors and etc.

SP20 CLEANER AND DEGREASER

PACKAGE:

- 450 ml/can

CONTACT CLEANER

AEROSOL PRODUCTS

CONTACT CLEANER

FEATURES:

- Electronic and electrical cleaner

- Grease and Oil removing agent

APPLICATION:

- Electronic and electrical components

- Hospital and health care equipment

- Household appliances / marine equipment

- Mould cleaner

SP10 CONTACT CLEANER

PACKAGE:

- 220 ml/can

- 450 ml/can

VARNISHCOTE CLEAR / RED

SEALANTS AND ADHESIVES

SEALXPERT VARNISHCOTE CLEAR / RED

FEATURES:

- Excellent oil and moisture resistance

- Excellent finish – tough, flexible, glossy, and durable

- Good water and salt water resistance

- Good adhesion

- High glass

APPLICATION:

- VC04C (Clear): Provide maximum protection against sunlight, water, sea spray, and chemical resistance on exterior wood boat surfaces, wood furniture and printed circuit boards

- VC04R (Red): Insulates transformers, coils, armature, motor windings, and various electric generator parts against arc and corona

SEALXPERT VARNISHCOTE

PACKAGE:

- 4 litres

CLEAR EPOXY WITH HARDENER

SEALANTS AND ADHESIVES

SEALXPERT CLEAR EPOXY WITH HARDENER

FEATURES:

-

- Strong 2-component epoxy with long working time

- Oil, chemical and impact resistant

- High temperature resistance

- Withstands rough handling

- Wide service temperature range

APPLICATION:

- Bonds metal, wood, masonry, ceramics, glass, dry concrete, chipboard, leather, cardboard, fabric, rubber and most plastics (except polyethylene, polypropylene, Teflon)

SEALXPERT CLEAR EPOXY WITH HARDENER

PACKAGE:

- 50 ml /pcs

CA496 CYANOACRYLATE ADHESIVE

CYANOACRYLATE ADHESIVES

SEALXPERT CA496 CYANOACRYLATE ADHESIVE

FEATURES:

- General purpose

- Medium viscosity

- Does not contain solvent, but highly polymerize with moisture in the air for a fast cure and high bond strength

- Fast cure

- Suitable for metal bonding

APPLICATION:

- Used for metal bonding

- Applicable to electronics, automobile, watercraft, precision machine and wood etc.

TECHNICAL DATA:

| Product No. | Typical Use | Max Gap (mm) | Colour (Uncured) | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture Time (sec) | Full Cure (hrs) |

| CA401 | Porous/Acidic surfaces | 0.1 | Transparent | 110 | 3,191 | -55 to 83 | < 20 | 24 |

| CA406 | Plastic/Electrometric | 0.05 | Transparent | 22-Dec | – | -55 to 83 | < 20 | 24 |

| CA480 | Impact/Vibration resistant | 0.1 | Black | 250 | 3,191 | -55 to 83 | < 40 | 24 |

| CA495 | Plastic/Rubber | 0.1 | Transparent | 45 | 2,756 | -55 to 83 | < 20 | 24 |

| CA496 | Metal parts | 0.1 | Transparent | 120 | 3,626 | -55 to 83 | < 20 | 24 |

SEALXPERT CA496 CYANOACRYLATE ADHESIVE

PACKAGE:

- 20 gram / bottle

CA495 CYANOACRYLATE ADHESIVE

CYANOACRYLATE ADHESIVES

SEALXPERT CA495 CYANOACRYLATE ADHESIVE

FEATURES:

- General purpose

- Medium to low viscosity

- Does not contain solvent, but highly polymerize with moisture in the air for a fast cure and high bond strength

APPLICATION:

- Ideal for filling gaps 0.004″ (0.1 mm)

- Used for bonding various materials such as rubber and plastic

TECHNICAL DATA:

| Product | Use | Max Gap (mm) | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (sec) | Full Cure (hrs) |

| CA401 | Porous & acidic surfaces | 0.1 | 110 | 3,191 | -55 to 83 | < 20 | 24 |

| CA406 | Plastic & electrometric | 0.05 | – | – | -55 to 83 | < 20 | 24 |

| CA480 | Impact & vibration resistant | 0.1 | 250 | 3,191 | -55 to 83 | < 40 | 24 |

| CA495 | Plastic & rubber | 0.1 | 45 | 2,756 | -55 to 83 | < 20 | 24 |

| CA496 | Metal parts | 0.1 | 120 | 3,626 | -55 to 83 | < 20 | 24 |

SEALXPERT CA495 CYANOACRYLATE ADHESIVE

PACKAGE:

- 20 gram / bottle

CA480 CYANOACRYLATE ADHESIVE

CYANOACRYLATE ADHESIVES

SEALXPERT CA480 CYANOACRYLATE ADHESIVE

FEATURES:

- Medium viscosity

- Impact resistant instant curing adhesive

- Contains no solvent, polymerizes highly with moisture in air and cures fast with high strength

- Good resistance in humid environments

APPLICATION:

- Used for difficult-to-bond material and impact resistant bonding, such as plastic, rubber, leather, wood and metal etc.

- For applications where shock resistance is required or shock or peel loads are present

- Suitable application includes precise electric industry, automobile industry, precise machinery industry, household electric appliance industry, wood industry, art ware industry, toy industry, marine, construction industry and audio equipment etc.

TECHNICAL DATA:

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (sec) |

| CA401 | Porous & acidic surfaces | 0.1 | Transparent | 110 | 3,191 (224 kg/cm²) | -55 to 83 | < 20 |

| CA406 | Plastic & electrometric | 0.05 | Transparent | 22-Dec | – | -55 to 83 | < 20 |

| CA480 | Impact & vibration resistant | 0.1 | Black | 250 | 3,191 (224 kg/cm²) | -55 to 83 | < 40 |

| CA495 | Plastic & rubber | 0.1 | Transparent | 45 | 2,756 (194 kg/cm²) | -55 to 83 | < 20 |

| CA496 | Metal parts | 0.1 | Transparent | 120 | 3,626 (255 kg/cm²) | -55 to 83 | < 20 |

SEALXPERT CA480 CYANOACRYLATE ADHESIVE

PACKAGE:

- 20 gram / bottle

CA406 CYANOACRYLATE ADHESIVE

CYANOACRYLATE ADHESIVES

SEALXPERT CA406 CYANOACRYLATE ADHESIVE

FEATURES:

- Low viscosity

- Instant adhesive designed especially for the fast bonding of plastics and rubbers

APPLICATION:

- Ideal for bonding of plastics and elastomeric materials where very fast fixture is required.

TECHNICAL DATA:

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Cure Time (hrs) |

| CA401 | Porous & acidic surfaces | 0.1 | Transparent | 110 | 3,191 (224 kg/cm²) | -55 to 83 | 24 |

| CA406 | Plastic & electrometric | 0.05 | Transparent | 22-Dec | – | -55 to 83 | 24 |

| CA480 | Impact & vibration | 0.1 | Black | 250 | 3,191 (224 kg/cm²) | -55 to 83 | 24 |

| CA495 | Plastic & rubber | 0.1 | Transparent | 45 | 2,756 (194 kg/cm²) | -55 to 83 | 24 |

| CA496 | Metal parts | 0.1 | Transparent | 120 | 3,626 (255 kg/cm²) | -55 to 83 | 24 |

SEALXPERT CA406 CYANOACRYLATE ADHESIVE

PACKAGE:

- 20 gram / bottle

CA401 CYANOACRYLATE ADHESIVE

CYANOACRYLATE ADHESIVES

SEALXPERT CA401 CYANOACRYLATE ADHESIVE

FEATURES:

-

- General purpose

- Medium viscosity

- Does not contain solvent, but highly polymerize with moisture in the air for a fast cure and high bond strength

APPLICATION:

- Used for bonding inert materials which are difficult to bond

- Ideal for coarse, porous and acidic surfaces such as wood, rubber, leather and paperboard bonding

TECHNICAL DATA:

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Cure Time (hrs) |

| CA401 | Porous & acidic surfaces | 0.1 | Transparent | 110 | 3,191 (224 kg/cm²) | -55 to 83 | 24 |

| CA406 | Plastic & electrometric | 0.05 | Transparent | 22-Dec | – | -55 to 83 | 24 |

| CA480 | Impact & vibration | 0.1 | Black | 250 | 3,191 (224 kg/cm²) | -55 to 83 | 24 |

| CA495 | Plastic & rubber | 0.1 | Transparent | 45 | 2,756 (194 kg/cm²) | -55 to 83 | 24 |

| CA496 | Metal parts | 0.1 | Transparent | 120 | 3,626 (255 kg/cm²) | -55 to 83 | 24 |

SEALXPERT CA401 CYANOACRYLATE ADHESIVE

PACKAGE:

- 20 gram / bottle

RC680 RETAINING COMPOUNDS

RETAINING COMPOUNDS

SEALXPERT RC680 RETAINING COMPOUNDS

FEATURES:

- High strength, medium viscosity

- Enhances bonding strength

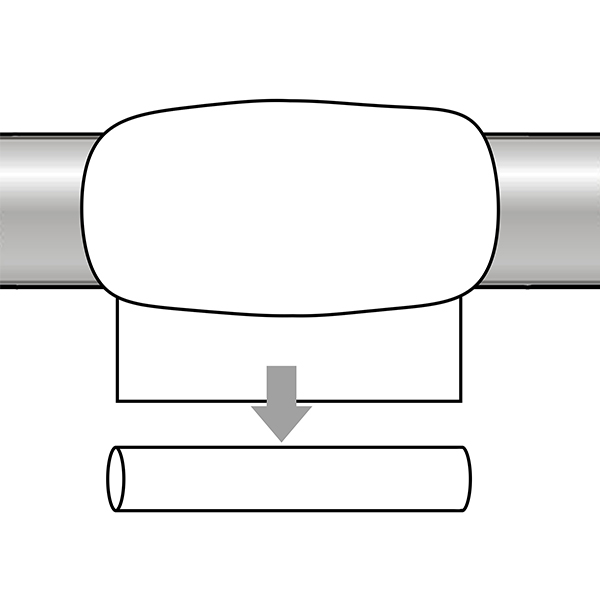

APPLICATION:

- Used for diametral clearance of less than 0.01” (0.25 mm) clearance fit or transition fit with the best fit clearance between 0.002” (0.05 mm) to 0.004” (0.10 mm)

- Replace press fit and prevent rust

- Used for slight rotating (worn) bearing, shaft sleeve etc. fittings, retain belt pulley, bushing, gear wheel, rotor, rebuild hole-shaft fitting parts and out-of-tolerance parts

- Designed for transition and interference fit.

TECHNICAL DATA

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (min) |

| RC603 | Slightly oil-contaminated | 0.13 | Green | 200 | > 2901 (> 204 kg/cm²) | -50 to 150 | 5 – 10 |

| RC620 | High temp (up to 232°C) | 0.3 | Green | 8,500 | > 2901 (> 204 kg/cm²) | -50 to 230 | 30 – 100 |

| RC638 | Maximum strength | 0.26 | Green | 2,500 | > 4496 (> 316 kg/cm²) | -50 to 150 | 5 – 10 |

| RC648 | High temp (up to 175°C) | 0.15 | Green | 500 | > 2611 (> 184 kg/cm²) | -50 to 175 | 5 – 15 |

| RC680 | Clearance/transition fit | 0.25 | Green | 1,250 | > 2756 (> 194 kg/cm²) | -50 to 150 | 10 – 15 |

SEALXPERT RC680 RETAINING COMPOUNDS

PACKAGE:

- 50 ml / bottle

RC648 RETAINING COMPOUNDS

RETAINING COMPOUNDS

SEALXPERT RC648 RETAINING COMPOUNDS

FEATURES:

- High strength, medium to low viscosity

- Withstand high temperature to 175 °C (347 °F)

- Fixture in 5 minutes

APPLICATION:

- Used for dynamic loading or periodic loading working conditions

- High temperature resistant, cures fast, retaining cylindrical assembly where fit clearance is less than 0.006” (0.15 mm)

- Designed for transition and interference fit

TECHNICAL DATA

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (min) |

| RC603 | Oil-contaminated surface | 0.13 | Green | 200 | > 2901 (> 204 kg/cm²) | -50 to 150 | 5 – 10 |

| RC620 | High temp (up to 232°C / 450°F) | 0.3 | Green | 8,500 | > 2901 (> 204 kg/cm²) | -50 to 230 | 30 – 100 |

| RC638 | Maximum strength | 0.26 | Green | 2,500 | > 4496 (> 316 kg/cm²) | -50 to 150 | 5 – 10 |

| RC648 | High temp (up to 175°C / 347°F) | 0.15 | Green | 500 | > 2611 (> 184 kg/cm²) | -50 to 175 | 5 – 15 |

| RC680 | Clearance/transition fit | 0.25 | Green | 1,250 | > 2756 (> 194 kg/cm²) | -50 to 150 | 10 – 15 |

SEALXPERT RC648 RETAINING COMPOUNDS

PACKAGE:

- 50 ml / bottle

RC638 RETAINING COMPOUNDS

RETAINING COMPOUNDS

SEALXPERT RC638 RETAINING COMPOUNDS

FEATURES:

- Maximum high strength, high viscosity

- Fixture in 5 minutes

APPLICATION:

- Used for retaining cylindrical assembly where fit clearance can approach 0.01” (0.26 mm) and where maximum strength at room temperature is required

- Lock bushings and sleeves into housings and on shafts

- Designed for transition and interference fit

TECHNICAL DATA

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (min) |

| RC603 | Oil-contaminated surface | 0.13 | Green | 200 | > 2901 (> 204 kg/cm²) | -50 to 150 | 5 – 10 |

| RC620 | High temp (up to 232°C / 450°F) | 0.3 | Green | 8,500 | > 2901 (> 204 kg/cm²) | -50 to 230 | 30 – 100 |

| RC638 | Maximum strength | 0.26 | Green | 2,500 | > 4496 (> 316 kg/cm²) | -50 to 150 | 5 – 10 |

| RC648 | High temp (up to 175°C / 347°F) | 0.15 | Green | 500 | > 2611 (> 184 kg/cm²) | -50 to 175 | 5 – 15 |

| RC680 | Clearance/transition fit | 0.25 | Green | 1,250 | > 2756 (> 194 kg/cm²) | -50 to 150 | 10 – 15 |

SEALXPERT RC638 RETAINING COMPOUNDS

PACKAGE:

- 50 ml / bottle

RC620 RETAINING COMPOUNDS

RETAINING COMPOUNDS

SEALXPERT RC620 RETAINING COMPOUNDS

FEATURES:

- Thixotropic viscosity

- Self-curing high temperature resistant

APPLICATION:

- Designed to retain cylindrical fittings which can endure high temperatures 232 °C (450 °F)

- Generally applicable for parts whose working temperature is 150 °C (302 °F) to 230°C (446 °F) (intermittent and continuous)

- Used to bond and retain automobile air valve sleeve, injection molding machine core sleeve, valve bushing, cylinder liner, plunger pin in steam hammer; seal or lock thread

TECHNICAL DATA

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (min) |

| RC603 | Oil-contaminated surface | 0.13 | Green | 200 | > 2901 (> 204 kg/cm²) | -50 to 150 | 5 – 10 |

| RC620 | High temp (up to 232°C / 450°F) | 0.3 | Green | 8,500 | > 2901 (> 204 kg/cm²) | -50 to 230 | 30 – 100 |

| RC638 | Maximum strength | 0.26 | Green | 2,500 | > 4496 (> 316 kg/cm²) | -50 to 150 | 5 – 10 |

| RC648 | High temp (up to 175°C / 347°F) | 0.15 | Green | 500 | > 2611 (> 184 kg/cm²) | -50 to 175 | 5 – 15 |

| RC680 | Clearance/transition fit | 0.25 | Green | 1,250 | > 2756 (> 194 kg/cm²) | -50 to 150 | 10 – 15 |

SEALXPERT RC620 RETAINING COMPOUNDS

PACKAGE:

- 50 ml / bottle

RC603 RETAINING COMPOUNDS

RETAINING COMPOUNDS

SEALXPERT RC603 RETAINING COMPOUNDS

FEATURES:

- High strength, low viscosity

- Good oil tolerance, can be used on surfaces with slight oil contamination

APPLICATION:

- Seals and secures cylindrical assemblies under 0.005” (0.13 mm ) diametrical clearance

- Designed for transition and interference fit

- Used for slightly oily surface and inert surface

TECHNICAL DATA

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Fixture (min) |

| RC603 | Oil-contaminated surface | 0.13 | Green | 200 | >2901 (>204 kg/cm²) | -50 to 150 | 5 – 10 |

| RC620 | High temp (up to 232°C) | 0.3 | Green | 8,500 | >2901 (>204 kg/cm²) | -50 to 230 | 30 – 100 |

| RC638 | Maximum strength | 0.26 | Green | 2,500 | >4496 (>316 kg/cm²) | -50 to 150 | 5 – 10 |

| RC648 | High temp (up to 175°C) | 0.15 | Green | 500 | >2611 (>184 kg/cm²) | -50 to 175 | 5 – 15 |

| RC680 | Clearance/transition fit | 0.25 | Green | 1,250 | >2756 (>194 kg/cm²) | -50 to 150 | 10 – 15 |

SEALXPERT RC603 RETAINING COMPOUNDS

PACKAGE:

- 50 ml / bottle

FS518 FLANGE SEALANTS

SEALXPERT FS518 FLANGE SEALANTS

FEATURES:

- Thixotropic viscosity

- Medium strength

- Provides resistance to low pressures immediately after assembly of flanges

APPLICATION:

- Used for sealing flange of aluminium alloy parts, or the rigid structure machining parts with minor flange migration, enduring temperature, pressure and stress

- Typically used as form-in-place gasket for motive power machines such as automobile, engineering machine, internal combustion engine, mining machine, pump etc.

TECHNICAL DATA:

| Property | FS510 | FS515 | FS518 |

| Typical Use | High temperature and solvent resistant | General purpose | Aluminium |

| Max Gap Fill | 0.25 mm | 0.25 mm | 0.25 mm |

| Uncured Colour | Pink | Purple | Red |

| Viscosity (mPa.s) | 40,000–140,000 | 1,200,000 (Thixotropic) | 900,000 |

| Specific Gravity | 1.10 g/cm³ | 1.10 g/cm³ | 1.10 g/cm³ |

SEALXPERT FS518 FLANGE SEALANTS

PACKAGE:

- 50 ml / tube

FS515 FLANGE SEALANTS

SEALXPERT FS515 FLANGE SEALANTS

FEATURES:

- Thixotropic viscosity

- General purpose

- Excellent solvent and chemical resistance

APPLICATION:

- Flexible gasket after cured, withstands slight flange movement caused by vibration

- Used for rigid machined parts flange sealing

- Applicable to motive power machines such as automobile, engineering machine, internal combustion engine, mining equipment, etc. for heavy loading

TECHNICAL DATA:

| Property | FS510 | FS515 | FS518 |

| Typical Use | High temperature and solvent resistant | General purpose | Aluminium |

| Max Gap Fill | 0.25 mm | 0.25 mm | 0.25 mm |

| Uncured Colour | Pink | Purple | Red |

| Viscosity (mPa.s) | 40,000–140,000 | 1,200,000 (Thixotropic) | 900,000 |

| Specific Gravity | 1.10 g/cm³ | 1.10 g/cm³ | 1.10 g/cm³ |

SEALXPERT FS515 FLANGE SEALANTS

PACKAGE:

- 50 ml / tube

FS510 FLANGE SEALANTS

FLANGE SEALANTS

SEALXPERT FS510 FLANGE SEALANTS

FEATURES:

- High viscosity

- Medium strength

- Excellent solvent and chemical resistance

- High temperature resistant

- Increases the torque capacity of assembled flanges

APPLICATION:

- Ideal for sealing rigid flange faces on transmissions and engine casings

- Ideal for use on rigid flanges where high temperature and chemical resistance are necessary

- General gasketing product suitable for hand dispensing or screen printing

TECHNICAL DATA:

| Property | FS510 | FS515 | FS518 |

| Typical Use | High temperature and solvent resistant | General purpose | Aluminium |

| Max Gap Fill | 0.25 mm | 0.25 mm | 0.25 mm |

| Uncured Colour | Pink | Purple | Red |

| Viscosity (mPa.s) | 40,000–140,000 | 1,200,000 (Thixotropic) | 900,000 |

| Specific Gravity | 1.10 g/cm³ | 1.10 g/cm³ | 1.10 g/cm³ |

SEALXPERT FS510 FLANGE SEALANTS

PACKAGE:

- 50 ml / tube

TS577 THREAD SEALANT

SEALXPERT TS577 THREAD SEALANT

FEATURES:

- High viscosity, thixotropic, high strength

- Contains no fillers and will not foul pipeline system

- Suitable for large gap sealing and fast curing

APPLICATION:

- Used for pipe thread sealing at rigorous operating condition or of large gap

- Typically used for sealing stainless steel pipe thread or pressure sealing of taper/straight pipe thread below M80

TECHNICAL DATA:

| Property | FS510 | FS515 | FS518 |

| Typical Use | High temperature and solvent resistant | General purpose | Aluminium |

| Max Gap Fill | 0.25 mm | 0.25 mm | 0.25 mm |

| Uncured Colour | Pink | Purple | Red |

| Viscosity (mPa.s) | 40,000–140,000 | 1,200,000 (Thixotropic) | 900,000 |

| Specific Gravity | 1.10 g/cm³ | 1.10 g/cm³ | 1.10 g/cm³ |

SEALXPERT TS577 THREAD SEALANT

PACKAGE:

- 50ml/bottle

TS567 THREAD SEALANT

SEALXPERT TS567 THREAD SEALANT

FEATURES:

- General purpose, low strength, coarse threads

- Prevents leaks due to vibrational loosening and other stresses

- Temperature resistance up to 250 °C (480 °F)

- Excellent chemical resistance

APPLICATION:

- Mainly used for instant sealing of large diameter tapered/tapered, tapered/straight pipe thread and stainless steel connector

- Prevent thread from corrosion

TECHNICAL DATA:

| Property | TS542 | TS545 | TS567 |

| Typical Use | Fine threads | Hydraulic and pneumatic pipeline thread sealing | General purpose, stainless steel pipe thread sealing |

| Max Diameter of Thread | M36 | M36, tapered | M80 |

| Uncured Colour | Brown | Purple | White |

| Viscosity (mPa.s) | 1,850 (thixotropic) | 14,000 (thixotropic) | 550,000 |

| Specific Gravity | 1.06 g/cm³ | 1.05 g/cm³ | 1.15 g/cm³ |

SEALXPERT TS567 THREAD SEALANT

PACKAGE:

- 50ml/bottle

TS545 THREAD SEALANT

SEALXPERT TS545 THREAD SEALANT

FEATURES:

- Thixotropic, low viscosity, low strength

- Good oil tolerance, can be used on surfaces with slight oil contamination

- Contains no fillers and will no foul pipeline system

APPLICATION:

- Typically used for sealing and locking high hydraulic pressure power system, ideal for under M36 tapered thread.

- Will not foul or jam hydraulic and pneumatic fittings on surface, can be used with slight oil contamination.

TECHNICAL DATA:

| Property | TS542 | TS545 | TS567 | TS577 |

|---|---|---|---|---|

| Typical Use | Fine threads | Hydraulic and pneumatic pipeline thread sealing | General purpose, stainless steel pipe thread sealing | Coarse thread sealing |

| Max Diameter of Thread | M36 | M36, tapered | M80 | M80, tapered/straight |

| Uncured Colour | Brown | Purple | White | Yellow |

| Viscosity (mPa.s) | 1,850 (thixotropic) | 14,000 (thixotropic) | 550,000 | 100,000 (thixotropic) |

| Specific Gravity | 1.06 g/cm³ | 1.05 g/cm³ | 1.15 g/cm³ | 1.10 g/cm³ |

| Max Sealing Pressure | 10,153 psi (714 kg/cm²) | 10,080 psi (709 kg/cm²) | 10,298 psi (724 kg/cm²) | 9,427 psi (663 kg/cm²) |

| Temperature Range | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) | -50 to 200°C (-58 to 392°F) | -50 to 150°C (-58 to 302°F) |

SEALXPERT TS545 THREAD SEALANT

PACKAGE:

- 50ml/bottle

TS542 THREAD SEALANT

THREAD SEALANT

SEALXPERT TS542 THREAD SEALANT

FEATURES:

- Thixotropic, low viscosity, medium strength

- Contains no fillers and will not foul pipeline system

APPLICATION:

- Used for sealing fine threads in pneumatic and hydraulic systems

- Typically used for sealing fine pipe thread under M36

TECHNICAL DATA:

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Shear Strength (Psi) | Temp. Range (°C) | Cure Time (hrs) |

| CA401 | Porous & acidic surfaces | 0.1 | Transparent | 110 | 3,191 (224 kg/cm²) | -55 to 83 | 24 |

| CA406 | Plastic & electrometric | 0.05 | Transparent | 22-Dec | – | -55 to 83 | 24 |

| CA480 | Impact & vibration | 0.1 | Black | 250 | 3,191 (224 kg/cm²) | -55 to 83 | 24 |

| CA495 | Plastic & rubber | 0.1 | Transparent | 45 | 2,756 (194 kg/cm²) | -55 to 83 | 24 |

| CA496 | Metal parts | 0.1 | Transparent | 120 | 3,626 (255 kg/cm²) | -55 to 83 | 24 |

SEALXPERT TS542 THREAD SEALANT

PACKAGE:

- 50ml/bottle

AT290 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT290 THREADLOCKER

FEATURES:

- Low viscosity, medium strength, high penetrability

- Wicking grade

- Excellent chemical resistance

APPLICATION:

- Prevent loosening and leakage from shock and vibration

- Used for locking and sealing pre-assembled threaded fasteners under M12

- Penetrate threads by capillary action

TECHNICAL DATA:

| Property | AT222 | AT242 | AT243 | AT262 | AT270 | AT271 | AT272 | AT277 | AT290 |

|---|---|---|---|---|---|---|---|---|---|

| Typical Use | M2-M8, removable | M8-M16, removable | M8-M20, oil contamination | M10-M26, permanent | M25, permanent | M16-M26, permanent | M25-M80, permanent | M24-M36, permanent | Under M12, wicking |

| Max Gap Fill | 0.13 mm | 0.13 mm | 0.13 mm | 0.13 mm | 0.13 mm | 0.13 mm | 0.25 mm | 0.25 mm | 0.10 mm |

| Uncured Colour | Purple | Blue | Blue | Red | Green | Red | Red-orange | Red | Green |

| Viscosity (mPa.s) | 1,200 | 1,700 | 2,250 | 1,800 | 500 | 500 | 4,000-15,000 | 7,000 | 12 |

| Specific Gravity | 1.05 | 1.05 | 1.05 | 1.10 | 1.10 | 1.12 | 1.11 | 1.12 | 1.08 |

| Breakaway Torque | 6 Nm | 12 Nm | 20 Nm | 22 Nm | 26 Nm | 27 Nm | 23 Nm | 30 Nm | 10 Nm |

| Prevail Torque | 4 Nm | 5 Nm | 7 Nm | 30 Nm | 36 Nm | 30 Nm | 25 Nm | 30 Nm | 26 Nm |

| Temperature Range | -50 to 150°C | -50 to 150°C | -50 to 150°C | -50 to 150°C | -50 to 150°C | -50 to 150°C | -55 to 200°C | -50 to 150°C | -50 to 150°C |

| Fixture Time | 10-20 min | 10-20 min | 10-20 min | 10-20 min | 10-20 min | 10-20 min | 40 min | 23-30 min | 5-15 min |

| Full Cure Time | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs |

SEALXPERT AT290 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT277 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT277 THREADLOCKER

FEATURES:

- High strength, high viscosity

- Excellent chemical resistance

- Good lubricity

- Heat and hand tools are required for disassembly

APPLICATION:

- Prevent loosening and leakage from shock and vibration

- Used for permanent locking and sealing M24 – M36 threaded fasteners, prevent thread from rust

- Typically used for large diameter thread locking and sealing

TECHNICAL DATA:

| Property | AT222 | AT242 | AT243 | AT262 | AT270 | AT271 | AT272 | AT277 | AT290 |

|---|---|---|---|---|---|---|---|---|---|

| Typical Use | M2-M8, removable | M8-M16, removable | M8-M20, oil contamination | M10-M26, permanent locking | M25, permanent locking | M16-M26, permanent locking | M25-M80, permanent locking | M24-M36, permanent locking | Under M12, wicking |

| Max Gap Fill | 0.13 mm | 0.13 mm | 0.13 mm | 0.13 mm | 0.13 mm | 0.13 mm | 0.25 mm | 0.25 mm | 0.10 mm |

| Uncured Colour | Purple | Blue | Blue | Red | Green | Red | Red-orange | Red | Green |

| Viscosity (mPa.s) | 1,200 (Thixotropic) | 1,700 (Thixotropic) | 2,250 (Thixotropic) | 1,800 (Thixotropic) | 500 | 500 | 4,000-15,000 (Thixotropic) | 7,000 | 12 |

| Specific Gravity | 1.05 g/cm³ | 1.05 g/cm³ | 1.05 g/cm³ | 1.10 g/cm³ | 1.10 g/cm³ | 1.12 g/cm³ | 1.11 g/cm³ | 1.12 g/cm³ | 1.08 g/cm³ |

| Breakaway Torque | 6 Nm | 12 Nm | 20 Nm | 22 Nm | 26 Nm | 27 Nm | 23 Nm | 30 Nm | 10 Nm |

| Prevail Torque | 4 Nm | 5 Nm | 7 Nm | 30 Nm | 36 Nm | 30 Nm | 25 Nm | 30 Nm | 26 Nm |

| Temperature Range | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) | -55 to 200°C (-67 to 392°F) | -50 to 150°C (-58 to 302°F) | -50 to 150°C (-58 to 302°F) |

| Fixture Time | 10-20 min | 10-20 min | 10-20 min | 10-20 min | 10-20 min | 10-20 min | 40 min | 23-30 min | 5-15 min |

| Full Cure Time | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 24 hrs | 2 hrs |

SEALXPERT AT277 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT272 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT272 THREADLOCKER

FEATURES:

- High temperature, high strength

- Withstands temperatures up to 232 °C (450 °F)

- Heat and hand tools are required for disassembly

APPLICATION:

- Permanent locking and sealing of threaded fasteners

- Prevents loosening and leakage from shock and vibration

- Used for locking and sealing of large bolts and studs (M25 and larger)

TECHNICAL DATA:

| Product No. | Use | Max Gap Fill | Colour | Viscosity (mPa.s) | Specific Gravity | Breakaway Torque (Nm) | Prevail Torque (Nm) | Temp Range (°C/°F) | Fixture (min) | Full Cure (hrs) |

| AT222 | M2-M8, removable | 0.13 mm | Purple | 1,200 (Thixotropic) | 1.05 g/cm³ | 6 | 4 | -50 to 150 (-58 to 302) | 10-20 | 24 |

| AT242 | M8-M16, removable | 0.13 mm | Blue | 1,700 (Thixotropic) | 1.05 g/cm³ | 12 | 5 | -50 to 150 (-58 to 302) | 10-20 | 24 |

| AT243 | M8-M20, slight oil contamination | 0.13 mm | Blue | 2,250 (Thixotropic) | 1.05 g/cm³ | 20 | 7 | -50 to 150 (-58 to 302) | 10-20 | 24 |

| AT262 | M10-M26, permanent locking/sealing | 0.13 mm | Red | 1,800 (Thixotropic) | 1.10 g/cm³ | 22 | 30 | -50 to 150 (-58 to 302) | 10-20 | 24 |

| AT270 | M25, permanent locking/sealing | 0.13 mm | Green | 500 | 1.10 g/cm³ | 26 | 36 | -50 to 150 (-58 to 302) | 10-20 | 24 |

| AT271 | M16-M26, permanent locking/sealing | 0.13 mm | Red | 500 | 1.12 g/cm³ | 27 | 30 | -50 to 150 (-58 to 302) | 10-20 | 24 |

| AT272 | M25-M80, permanent locking/sealing | 0.25 mm | Red-orange | 4,000–15,000 (Thixotropic) | 1.11 g/cm³ | 23 | 25 | -55 to 200 (-67 to 392) | 40 | 24 |

| AT277 | M24-M36, permanent locking/sealing | 0.25 mm | Red | 7,000 | 1.12 g/cm³ | 30 | 30 | -50 to 150 (-58 to 302) | 23-30 | 24 |

| AT290 | Under M12, wicking grade | 0.10 mm | Green | 12 | 1.08 g/cm³ | 10 | 26 | -50 to 150 (-58 to 302) | 5-15 | 24 |

SEALXPERT AT272 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT271 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT271 THREADLOCKER

FEATURES:

- High strength, medium to low viscosity

- Excellent chemical resistance

- Heat and hand tools are required for disassembly

- Good lubricity

APPLICATION:

- Prevent loosening and leakage from shock and vibration

- Used for permanent locking and sealing M16 – M26 (Ideal for under M22) threaded fasteners, prevent thread from rust

- Typically used for stud end locking (such as cylinder head stud)

TECHNICAL DATA:

| Product No. | Typical Use | Max Gap Fill | Colour | Viscosity (mPa.s) | Specific Gravity | Breakaway Torque (Nm) | Prevail Torque (Nm) | Temperature Range (°C/°F) | Fixture (min) | Full Cure (hrs) |

| AT222 | M2 – M8, removable | 0.13 mm | Purple | 1,200 (Thixotropic) | 1.05 g/cm³ | 6 | 4 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT242 | M8-M16, removable | 0.13 mm | Blue | 1,700 (Thixotropic) | 1.05 g/cm³ | 12 | 5 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT243 | M8-M20, slight oil contamination | 0.13 mm | Blue | 2,250 (Thixotropic) | 1.05 g/cm³ | 20 | 7 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT262 | M10-M26, permanent locking and sealing | 0.13 mm | Red | 1,800 (Thixotropic) | 1.10 g/cm³ | 22 | 30 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT270 | M25, permanent locking and sealing | 0.13 mm | Green | 500 | 1.10 g/cm³ | 26 | 36 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT271 | M16-M26, permanent locking and sealing | 0.13 mm | Red | 500 | 1.12 g/cm³ | 27 | 30 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT272 | M25-M80, permanent locking and sealing | 0.25 mm | Red-orange | 4,000–15,000 (Thixotropic) | 1.11 g/cm³ | 23 | 25 | -55 to 200 (-67 to 392) | 40 | 24 |

| AT277 | M24-M36, permanent locking and sealing | 0.25 mm | Red | 7,000 | 1.12 g/cm³ | 30 | 30 | -50 to 150 (-58 to 302) | 23–30 | 24 |

| AT290 | Under M12, wicking grade | 0.10 mm | Green | 12 | 1.08 g/cm³ | 10 | 26 | -50 to 150 (-58 to 302) | 5–15 | 24 |

SEALXPERT AT271 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT270 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT270 THREADLOCKER

FEATURES:

- Low viscosity, high strength

- Heat and hand tools are required for disassembly

- Excellent chemical resistance

- Good lubricity

APPLICATION:

- Prevent loosening and leakage from shock and vibration

- Prevent rusty threads

- Used for locking and sealing threaded fasteners of M25 and larger

TECHNICAL DATA:

| Product No. | Typical Use | Max Gap Fill | Colour | Viscosity (mPa.s) | Specific Gravity | Breakaway Torque (Nm) | Prevail Torque (Nm) | Temperature Range (°C/°F) | Fixture Time (min) | Full Cure (hrs) |

| AT222 | M2-M8, removable | 0.13 mm | Purple | 1,200 (Thixotropic) | 1.05 g/cm³ | 6 | 4 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT242 | M8-M16, removable | 0.13 mm | Blue | 1,700 (Thixotropic) | 1.05 g/cm³ | 12 | 5 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT243 | M8-M20, slight oil contamination | 0.13 mm | Blue | 2,250 (Thixotropic) | 1.05 g/cm³ | 20 | 7 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT262 | M10-M26, permanent locking and sealing | 0.13 mm | Red | 1,800 (Thixotropic) | 1.10 g/cm³ | 22 | 30 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT270 | M25, permanent locking and sealing | 0.13 mm | Green | 500 | 1.10 g/cm³ | 26 | 36 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT271 | M16-M26, permanent locking and sealing | 0.13 mm | Red | 500 | 1.12 g/cm³ | 27 | 30 | -50 to 150 (-58 to 302) | 10–20 | 24 |

| AT272 | M25-M80, permanent locking and sealing | 0.25 mm | Red-orange | 4,000–15,000 (Thixotropic) | 1.11 g/cm³ | 23 | 25 | -55 to 200 (-67 to 392) | 40 | 24 |

| AT277 | M24-M36, permanent locking and sealing | 0.25 mm | Red | 7,000 | 1.12 g/cm³ | 30 | 30 | -50 to 150 (-58 to 302) | 23–30 | 24 |

| AT290 | Under M12, wicking grade | 0.10 mm | Green | 12 | 1.08 g/cm³ | 10 | 26 | -50 to 150 (-58 to 302) | 5–15 | 24 |

SEALXPERT AT270 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT262 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT262 THREADLOCKER

FEATURES:

- Medium to high strength, thixotropic viscosity

- Excellent chemical resistance

- Good lubricity

- Easy removal, parts can be separated with hand tools

APPLICATION:

- Prevent loosening and leakage from shock and vibration

- Used for permanent locking and sealing M10 – M26 (Ideal for under M20) threaded fasteners

- Prevent rusty threads

- Thread locking, sealing and engine plug sealing

TECHNICAL DATA:

| Product | Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Specific Gravity | Temp Range (°C) | Fixture (min) | Full Cure (hr) | Breakaway Torque (Nm) | Prevail Torque (Nm) |

| AT222 | M2-M8, removable | 0.13 | Purple | 1,200 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10-20 | 24 | 6 | 4 |

| AT242 | M8-M16, removable | 0.13 | Blue | 1,700 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10-20 | 24 | 12 | 5 |

| AT243 | M8-M20, slight oil contamination | 0.13 | Blue | 2,250 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10-20 | 24 | 20 | 7 |

| AT262 | M10-M26, permanent locking & sealing | 0.13 | Red | 1,800 (Thixotropic) | 1.1 | -50 to 150 (-58 to 302) | 10-20 | 24 | 22 | 30 |

| AT270 | M25, permanent locking & sealing | 0.13 | Green | 500 | 1.1 | -50 to 150 (-58 to 302) | 10-20 | 24 | 26 | 36 |

| AT271 | M16-M26, permanent locking & sealing | 0.13 | Red | 500 | 1.12 | -50 to 150 (-58 to 302) | 10-20 | 24 | 27 | 30 |

| AT272 | M25-M80, permanent locking & sealing | 0.25 | Red-orange | 4,000-15,000 (Thixotropic) | 1.11 | -55 to 200 (-67 to 392) | 40 | 24 | 23 | 25 |

| AT277 | M24-M36, permanent locking & sealing | 0.25 | Red | 7,000 | 1.12 | -50 to 150 (-58 to 302) | 23-30 | 24 | 30 | 30 |

| AT290 | Under M12, wicking grade | 0.1 | Green | 12 | 1.08 | -50 to 150 (-58 to 302) | 5-15 | 24 | 10 | 26 |

SEALXPERT AT262 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT243 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to

fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT243 THREADLOCKER

FEATURES:

- Medium strength, thixotropic

- Easy removal, parts can be separated with hand tools

- Good oil resistance, can be used on the surface with slight oil contamination

- Controlled lubricity for accurate clamp loads

APPLICATION:

- Prevent threaded fasteners from loosening and leakage

- Used for locking and sealing M8 – M20 (Ideal for under M18) threaded fasteners

- Typically suitable for inert surface, such as stainless steel and electroplated surface

TECHNICAL DATA:

| Product | Typical Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Specific Gravity | Temp Range (°C) | Fixture Time (min) | Full Cure Time (hr) | Breakaway Torque (Nm) | Prevail Torque (Nm) |

| AT222 | M2 – M8, removable | 0.13 | Purple | 1,200 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 6 | 4 |

| AT242 | M8 – M16, removable | 0.13 | Blue | 1,700 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 12 | 5 |

| AT243 | M8 – M20, slight oil contamination | 0.13 | Blue | 2,250 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 20 | 7 |

| AT262 | M10 – M26, permanent locking & sealing | 0.13 | Red | 1,800 (Thixotropic) | 1.1 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 22 | 30 |

| AT270 | M25, permanent locking & sealing | 0.13 | Green | 500 | 1.1 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 26 | 36 |

| AT271 | M16 – M26, permanent locking & sealing | 0.13 | Red | 500 | 1.12 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 27 | 30 |

| AT272 | M25 – M80, permanent locking & sealing | 0.25 | Red-orange | 4,000 – 15,000 (Thixotropic) | 1.11 | -55 to 200 (-67 to 392) | 40 | 24 | 23 | 25 |

| AT277 | M24 – M36, permanent locking & sealing | 0.25 | Red | 7,000 | 1.12 | -50 to 150 (-58 to 302) | 23 – 30 | 24 | 30 | 30 |

| AT290 | Under M12, wicking grade | 0.1 | Green | 12 | 1.08 | -50 to 150 (-58 to 302) | 5 – 15 | 24 | 10 | 26 |

SEALXPERT AT243 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

AT242 THREADLOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT242 THREADLOCKER

FEATURES:

- Medium strength, thixotropic viscosity

- Controlled lubricity for accurate clamp loads

- Easy removal, parts can be separated with hand tools

APPLICATION:

- Used for locking and sealing M8 – M16 (Ideal below M8) threaded fasteners, prevent loosening, and leakage from shock and vibration

TECHNICAL DATA:

| Product | Typical Use | Max Gap (mm) | Colour | Viscosity (mPa.s) | Specific Gravity | Temp Range (°C) | Fixture Time (min) | Full Cure Time (hr) | Breakaway Torque (Nm) | Prevail Torque (Nm) |

| AT222 | M2 – M8, removable | 0.13 | Purple | 1,200 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 6 | 4 |

| AT242 | M8 – M16, removable | 0.13 | Blue | 1,700 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 12 | 5 |

| AT243 | M8 – M20, slight oil contamination | 0.13 | Blue | 2,250 (Thixotropic) | 1.05 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 20 | 7 |

| AT262 | M10 – M26, permanent locking & sealing | 0.13 | Red | 1,800 (Thixotropic) | 1.1 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 22 | 30 |

| AT270 | M25, permanent locking & sealing | 0.13 | Green | 500 | 1.1 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 26 | 36 |

| AT271 | M16 – M26, permanent locking & sealing | 0.13 | Red | 500 | 1.12 | -50 to 150 (-58 to 302) | 10 – 20 | 24 | 27 | 30 |

| AT272 | M25 – M80, permanent locking & sealing | 0.25 | Red-orange | 4,000 – 15,000 (Thixotropic) | 1.11 | -55 to 200 (-67 to 392) | 40 | 24 | 23 | 25 |

| AT277 | M24 – M36, permanent locking & sealing | 0.25 | Red | 7,000 | 1.12 | -50 to 150 (-58 to 302) | 23 – 30 | 24 | 30 | 30 |

| AT290 | Under M12, wicking grade | 0.1 | Green | 12 | 1.08 | -50 to 150 (-58 to 302) | 5 – 15 | 24 | 10 | 26 |

SEALXPERT AT242 THREADLOCKER

PACKAGE:

- 50ml/bottle

AT222 THREAD LOCKER

THREADLOCKER

Threadlocker, also known as thread-locking fluid, is applied to threads of fasteners such as screws and bolts to fill up to gaps and void spaces between metal components, and to mechanically bond the metal components together.

SEALXPERT AT222 THREAD LOCKER

FEATURES:

- Thixotropic viscosity, low strength

- Easy removal, parts can be separated with hand tools

APPLICATION:

- Prevent threaded fasteners from vibration and leakage

- Used for locking and sealing M2 – M8 (ideal for under M6)

- Especially suitable for situation where easy disassembly is available, adjust locating screw, small diameter or long threaded fasteners

TECHNICAL DATA:

| Product No. | Typical Use | Max Gap Fill (mm) | Uncured Colour | Viscosity (mPa.s) | Curing Speed | Specific Gravity (g/cm³) | Breakaway Torque (Nm) | Prevail Torque (Nm) | Temperature Range (°C) | Fixture Time (min) |

| AT222 | M2 – M8, removable | 0.13 | Purple | 1,200 | Thixotropic | 1.05 | 6 | 4 | -50 to 150 (-58 to 302) | 10 – 20 |

| AT242 | M8 – M16, removable | 0.13 | Blue | 1,700 | Thixotropic | 1.05 | 12 | 5 | -50 to 150 (-58 to 302) | 10 – 20 |

| AT243 | M8 – M20, slight oil contamination | 0.13 | Blue | 2,250 | Thixotropic | 1.05 | 20 | 7 | -50 to 150 (-58 to 302) | 10 – 20 |

| AT262 | M10 – M26, permanent locking and sealing | 0.13 | Red | 1,800 | Thixotropic | 1.1 | 22 | 30 | -50 to 150 (-58 to 302) | 10 – 20 |

| AT270 | M25, permanent locking and sealing | 0.13 | Green | 500 | None | 1.1 | 26 | 36 | -50 to 150 (-58 to 302) | 10 – 20 |

| AT271 | M16 – M26, permanent locking and sealing | 0.13 | Red | 500 | None | 1.12 | 27 | 30 | -50 to 150 (-58 to 302) | 10 – 20 |

| AT272 | M25 – M80, permanent locking and sealing | 0.25 | Red-orange | 4,000 – 15,000 | Thixotropic | 1.11 | 23 | 25 | -55 to 200 (-67 to 392) | 40 |

| AT277 | M24 – M36, permanent locking and sealing | 0.25 | Red | 7,000 | None | 1.12 | 30 | 30 | -50 to 150 (-58 to 302) | 23 – 30 |

| AT290 | Under M12, wicking grade | 0.1 | Green | 12 | None | 1.08 | 10 | 26 | -50 to 150 (-58 to 302) | 5 – 15 |

SEALXPERT AT222 THREAD LOCKER

PACKAGE:

- 50 ml / bottle

ACU10 UNDERWATER EPOXY COATING

EPOXY COATING & MARINE CHOCK

ACU10 UNDERWATER EPOXY COATING

FEATURES:

- Two-component epoxy repair compound

- Provides a rock-hard protective surface

- Provides excellent protection against corrosion of metals and erosion and deterioration of concrete or wood

APPLICATION:

- Designed to be applied in underwater and splash zone environments

- Repair boat hulls, buoys, seawalls, docks, bridge abutments, etc.

TECHNICAL DATA:

| Property | Value |

| Colour | White |

| Pot Life | 65 min |

| Flash Point | > 121°C (250°F) |

| Hardness | 72 Shore D |

ACU10 UNDERWATER EPOXY COATING

PACKAGE:

- 10 litres/set

ACC10 ANTI-CORROSIVE EPOXY COATING

EPOXY COATING & MARINE CHOCK

ACC10 ANTI-CORROSIVE EPOXY COATING

FEATURES:

- Two-component

- High adhesion strength

- Excellent alkali and acid resistance

APPLICATION:

- FRP storage tanks, pipes, vessels, ducts, and on-site maintenance projects, particularly in chemical processing, pulp and paper operations, including chlorine dioxide bleaching towers.

TECHNICAL DATA:

| Property | Value |

| Colour | Clear |

| Mix Ratio (by weight) | 3.3:1 |

| Mix Ratio (by volume) | 2.5:1 |

| Density | 1.07 |

ACC10 ANTI-CORROSIVE EPOXY COATING

PACKAGE:

- 10 litres/set

MC38 MARINE CHOCK

EPOXY COATING & MARINE CHOCK

MC38 MARINE CHOCK

FEATURES:

- Two-part pourable chocking compound with excellent mechanical strength

- Allow pouring up to 80mm thickness

- High compressive strength and impact strength

- Excellent resistant to chemicals

- Applicable to mounting main engines, auxiliary gears, compressors, pumps, thrust and support bearings, etc.

APPLICATION:

- Developed for chocking marine main propulsion and auxiliary machinery