FIBERGLASS REPAIR TAPE

WRAP SEAL PLUS FIBERGLASS REPAIR TAPE

FIBERGLASS REPAIR TAPE

WRAP SEAL PLUS FIBERGLASS REPAIR TAPE

FEATURES:

- Remediate, repairs and reinforces

- Durable, strong and permanent

- Restore pipes to original strength

APPLICATION:

- Applied onto thinning pipe walls for pipeline reinforcement

- Improve hoop strength of pipeline after repair

- Suitable for pipe diameter up to 60″ (1524 mm)

- Applicable for pipeline temperature up to 280 °C (536 °F)

TECHNICAL DATA:

| Property | Value |

|---|---|

| Tensile Modulus | 3.8 x 10⁶ psi (267,166 kg/cm²) |

| Tensile Strength | 65,000 psi (4570 kg/cm²) |

| Flexural Modulus | 3.6 x 10⁶ psi (253,105 kg/cm²) |

| Flexural Strength | 53,100 psi (3733 kg/cm²) |

| Compressive Strength | 28,500 psi (2004 kg/cm²) |

| Dielectric Strength | 20,000 Volts |

| Hardness | 85 Shore D |

WRAP SEAL PLUS CORROSION REPAIR PROCEDURE:

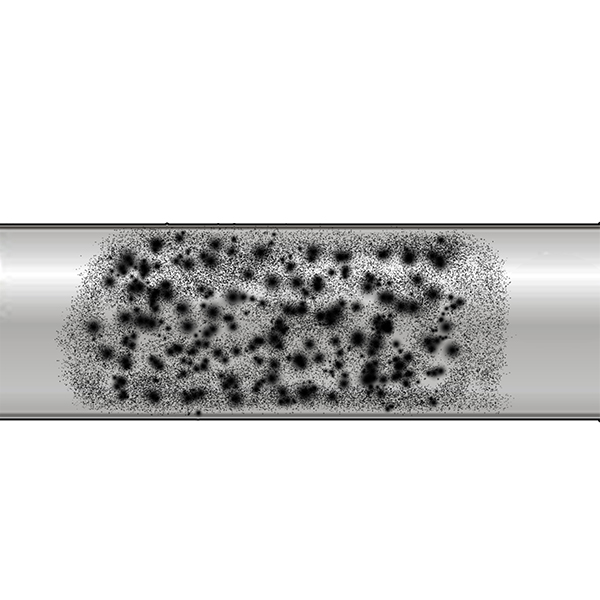

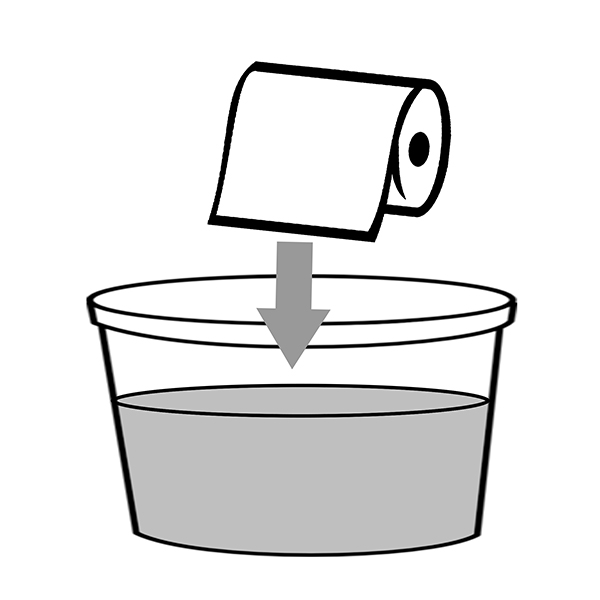

| Corroded pipe surface |  | Immerse Wrap Seal PLUS Fiberglass Repair Tape into water |

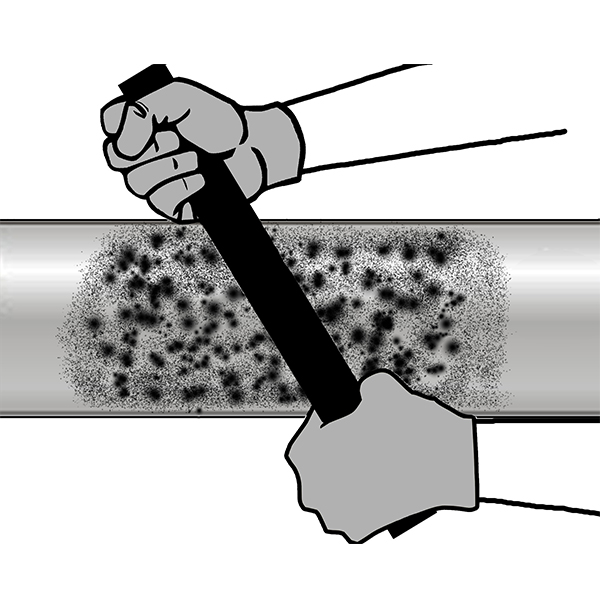

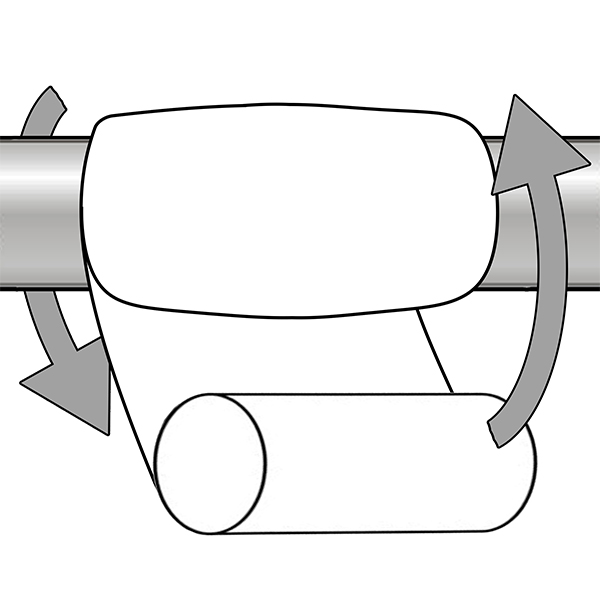

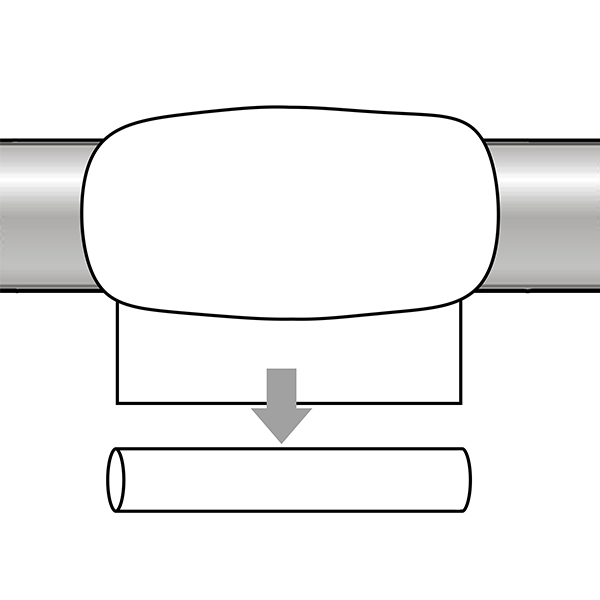

| Roughen the area to be repaired |  | Wrap the fiberglass repair tape as tightly and evenly as possible, with at least 50% overlap over affected pipe length |

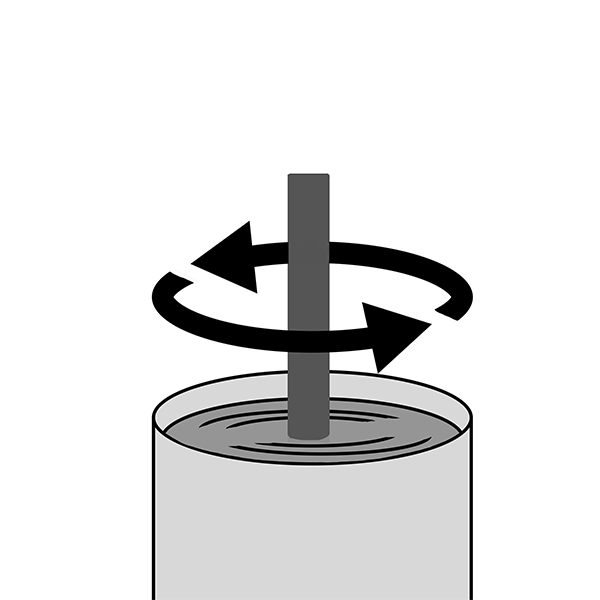

| Mix and stir Wrap Seal PLUS Resin and Activator for at least 1 minute until well mixed |  | Discard the plastic tube at the end of the roll |

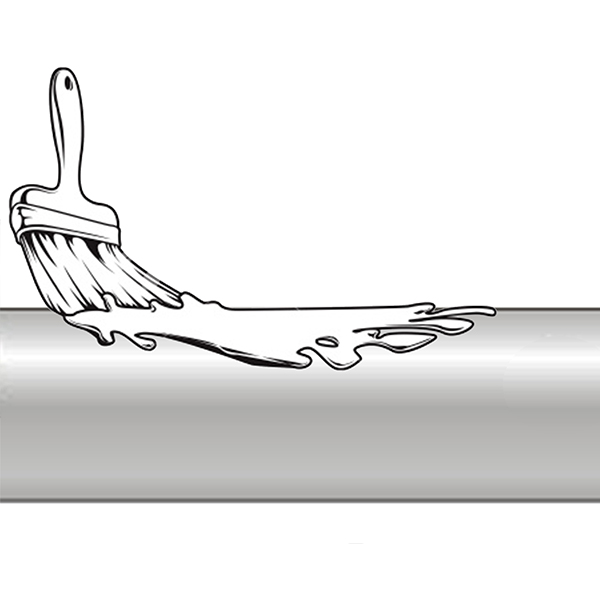

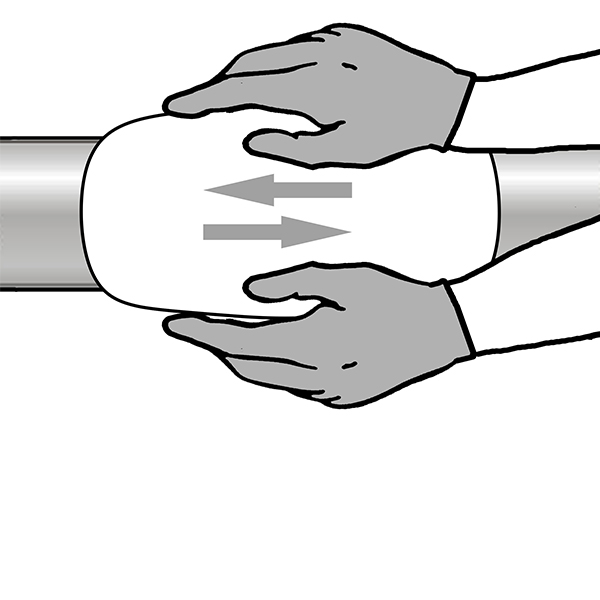

| Apply two coats of activated resin evenly over the area to be repaired and allow to cure |  | Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance |

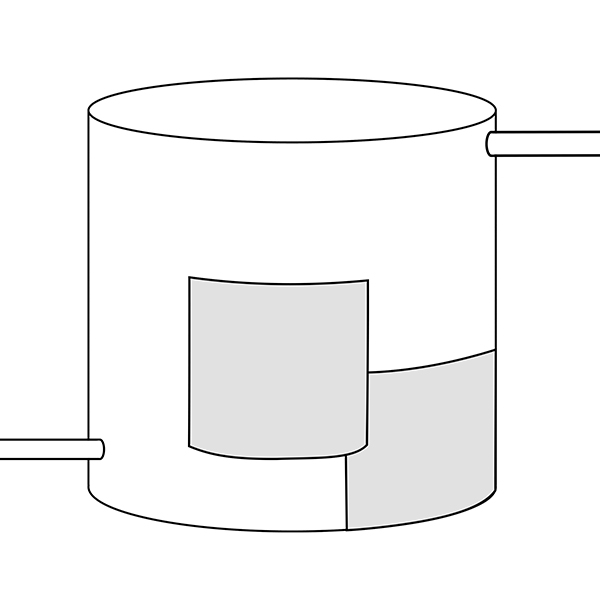

FLAT SURFACE/TANK

* Apply Several layers of wrap Seal PLUS Surface Tissue or Wrap Seal Plus Chopped

Strand Mat onto the affected area.

WRAP SEAL PLUS FIBERGLASS REPAIR TAPE

PACKAGE:

- 2″ x 5′ (50 mm x 1.5 m)

- 2″ x 6′ (50 mm x 1.8 m)

- 2″ x 12′ (50 mm x 3.6 m)

- 3″ x 9′ (75 mm x 2.7 m)

- 4″ x 12′ (100 mm x 3.6 m)

- 4″ x 20′ (100 mm x 6 m)

- 4″ x 30′ (100 mm x 9 m)

- 6″ x 20′ (150 mm x 6 m)

- 6″ x 30′ (150 mm x 9 m)