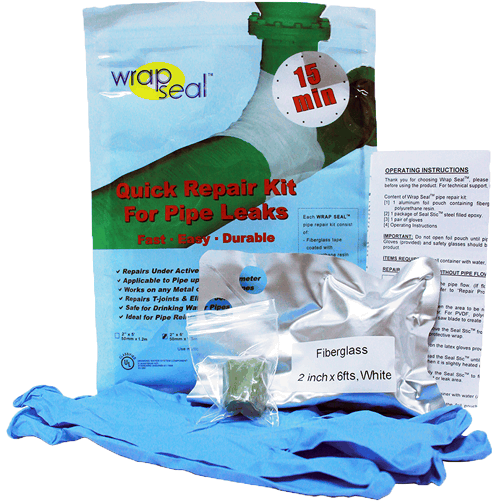

LEAK REPAIR KIT

WRAP SEAL QUICK REPAIR KIT FOR PIPE LEAKS

LEAK REPAIR KIT

WRAP SEAL QUICK REPAIR KIT FOR PIPE LEAKS

FEATURES:

- Repairs leak in 30 minutes

- Applicable to pipes up to 18″ (457 mm) diameter

- Applicable on any metal or non-metal pipes

- Repairs T-joint, elbow joint, valve thread, valve body

- Withstand pressure up to 400 psi (28 kg/cm2)

- Withstand temperature up to 200 °C (392 °F)

- Safe for drinking water and resistant to most chemicals

- Reinforce and strengthen pipe after repair

- Permanent repair and extend service life of pipes

APPLICABLE MATERIAL:

- Steel

- Copper

- Aluminium

- Galvanized steel

- PVC

- CPVC

- Stainless steel

- Polyethylene

- Polypropylene

- Cast-iron

- Concrete

- FRP/GRE

CHEMICAL RESISTANCE:

- Oil

- Water (drinking water, wastewater, steam)

- Solvents (acetone, toluene, MEK, ethyl alcohol)

- Mild acids (hydrochloric acid, sulfuric acid) and alkalis

- Chemical (ethylene glycol, xylenes, ammonia)

- Hydrocarbons

- Bases

- Slurries

- Fuels (petroleum, diesels, gasoline)

- Gases (LNG, LPG)

- Organic salts

WORKING TIME (FIBERGLASS TAPE):

1 minute at 30 °C (86 °F)

CURING TIME:

- 30 minutes at 30 °C (86 °F)

- Heat may be applied to decrease curing time

- Unopened foil pouch may be immerse in cold water prior to repair to add working and curing time.

APPLICATION:

- Pipe repairs

- offline repairs

- sealing joints

- hazardous material spill control

- reinforce thinning walls

- Abrasion protection

- Structural reinforcement

- Repairs in hard to reach areas

- Underwater repairs

OPERATING TEMPERATURE:

- Continuous – From -29 °C (-20 °F) up to 200 °C (392 °F)

- Intermittent – From 200 °C (392 °F) up to 320 °C (570 °F)

OPERATING PRESSURE:

- Recommended for pressure up to 400 psi (28 kg/cm2)

- (Results vary depending on pipe size, type of pipe, hole size, pipe content and method of application)

APPLICABLE INDUSTRIES:

| Building & Facilities |  | Offshore |

| Electronics |  | Food Processing |

| Industrial Processing |  | Petrochemical |

| Irrigation |  | Pharmaceutical |

| Oil & Gas |  | Power Generation |

| Chemical |  | Pulp & Paper |

| Manufacturing Plants |  | Wastewater |

| Marine |  | Water Distribution |

| Military |

TECHNICAL DATA:

| Pressure tested | : | 1/2″ (15 mm) steel pipe with 1/8″ (3 mm) hole when repaired with Wrap Seal withstands 4000 psi (281 kg/cm2) |

| 1/2″ (15 mm) steel pipe with 1/2″ (13 mm) hole when repaired with Wrap Seal withstands 600 psi (42 kg/cm2) | ||

| Tensile strength | : | 3920 psi (276 kg/cm2) |

| Bond strength | : | 230 psi (16 kg/cm2) |

| Tensile elongation | : | 1.2 % ± 0.7 % |

| Compressive strength | : | 13750 ± 530 psi (967 ± 37 kg/cm2) |

| Yield strength | : | 2260 psi (159 kg/cm2) |

| Cured hardness | : | 82 Shore D |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| ½” (15mm) | 1 A | 1 A | 1 A |

| ¾” (20mm) | 1 A | 1 A | 1 A |

| 1″ (25mm) | 1 A | 1 A | 2 A |

| 1¼” (32mm) | 1 A | 2 A | 3 A |

| 1½” (40mm) | 2 A | 2 A | 1 B |

| 2″ (50mm) | 1 B | 1 B | 1 B |

| 2½” (65mm) | 1 B | 1 B | 2 C |

| 3″ (80mm) | 1 B | 2 C | 2 C |

| 4″ (100mm) | 1 B | 2 C | 3 C |

| Pipe size | Number of rolls / size required | ||

| 50 psi (4 kg/cm2) 10 plys | 150 psi (11 kg/cm2) 15 plys | 400 psi (28 kg/cm2) 20 plys | |

| 5″ (125mm) | 2 C | 2 C | 3 C |

| 6″ (150mm) | 2 C | 2 C | 4 C |

| 8″ (200mm) | 2 C | 3 C | 5 C |

| 10″ (250mm) | 3 C | 4 C | 6 C |

| 12″ (300mm) | 4 C | 5 C | 8 C |

| 14″ (350mm) | 4 C | 6 C | 8 C |

| 16″ (400mm) | 5 C | 7 C | 9 C |

| 18″ (450mm) | 5 C | 8 C | 9 C |

| Roll size | A (2″ x 5′) (50mm x 1.2m) | A (2″ x 6′) (50mm x 1.8m) | B (2″ x 12′) (50mm x 3.6m) | B (3″ x 9′) (75mm x 2.7m) | C (4″ x 12′) (100mm x 3.6m) |

WRAP SEAL OFFLINE LEAK REPAIR PROCEDURE:

| Stop the pipe flow |

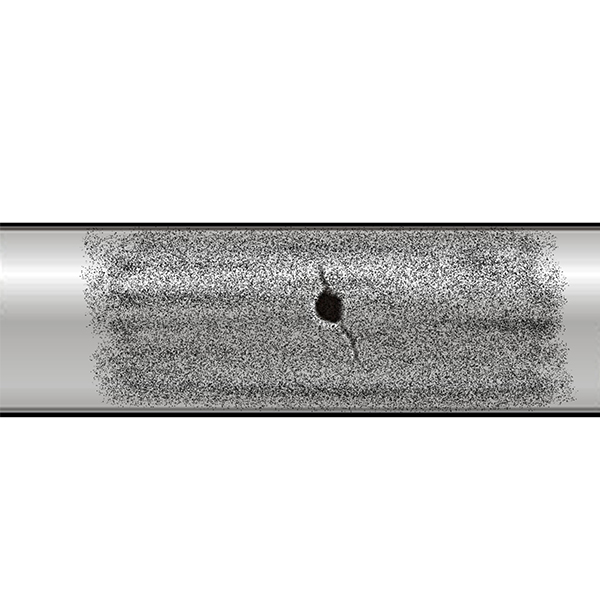

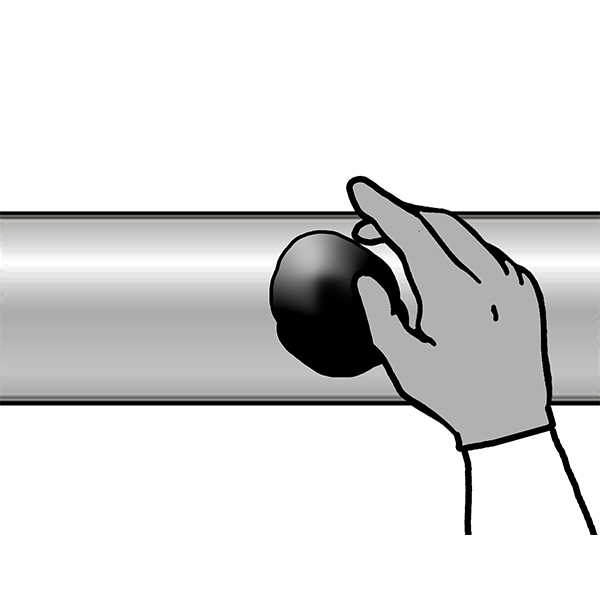

| Roughen the area to be repaired |

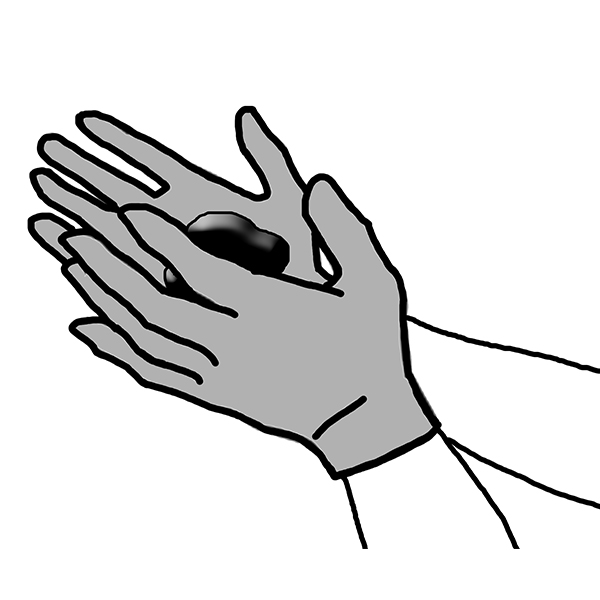

| Knead the Seal Stic |

| Apply the Seal Stic to fill in holes or crack of the damaged or leak area. |

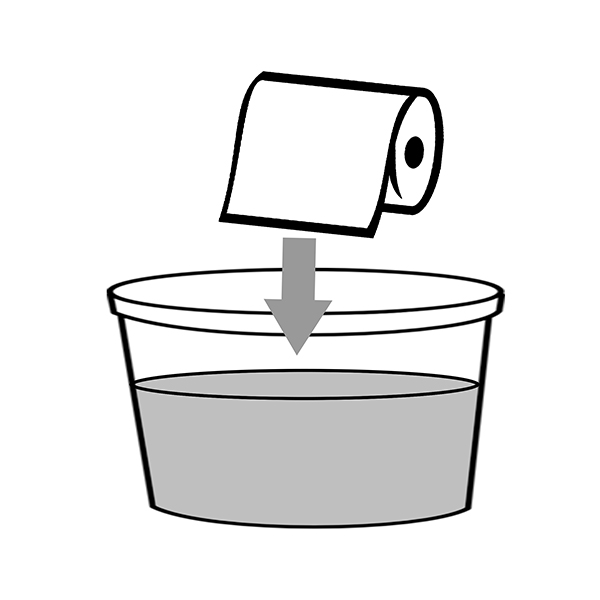

| Immerse the Wrap Seal Fiberglass Tape into water |

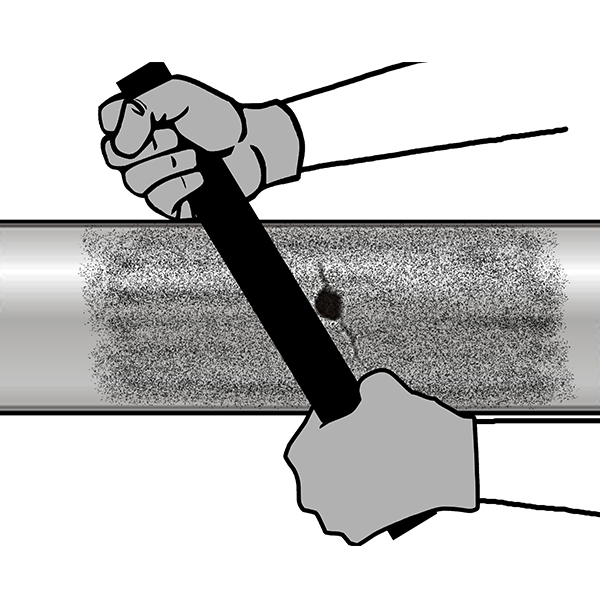

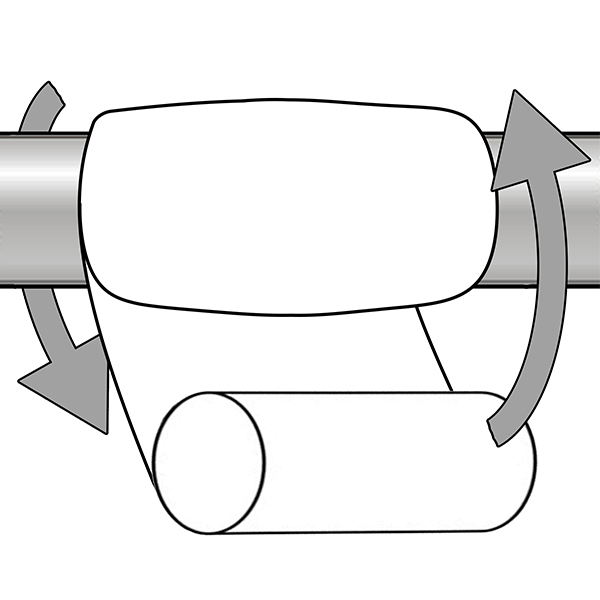

| Wrap the Wrap Seal Fiberglass Tape around the repair area as tightly and evenly as possible, using the entire roll |

| Discard the plastic tube at the end of the roll |

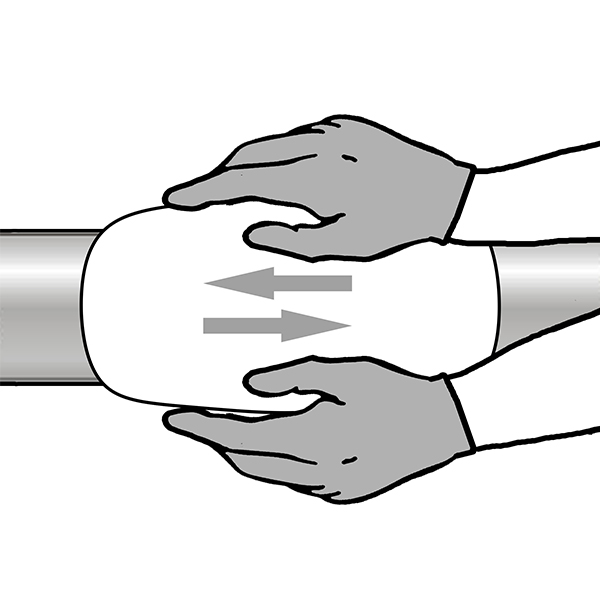

| Wet gloves in water and quickly compress the bubbling resins back into the fiberglass wrap |

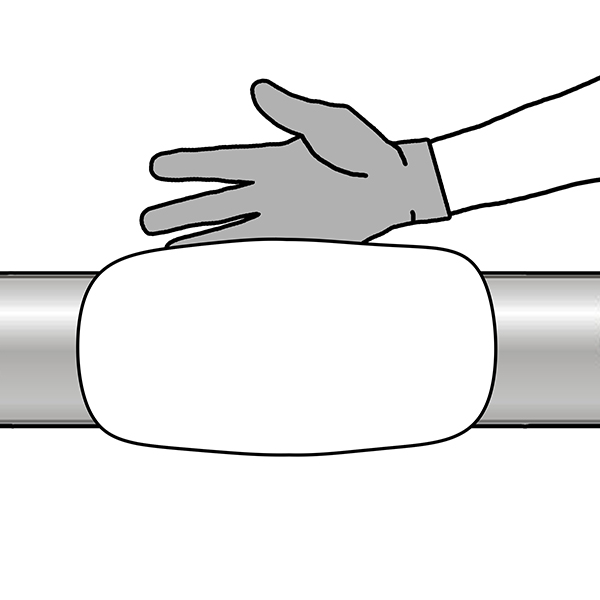

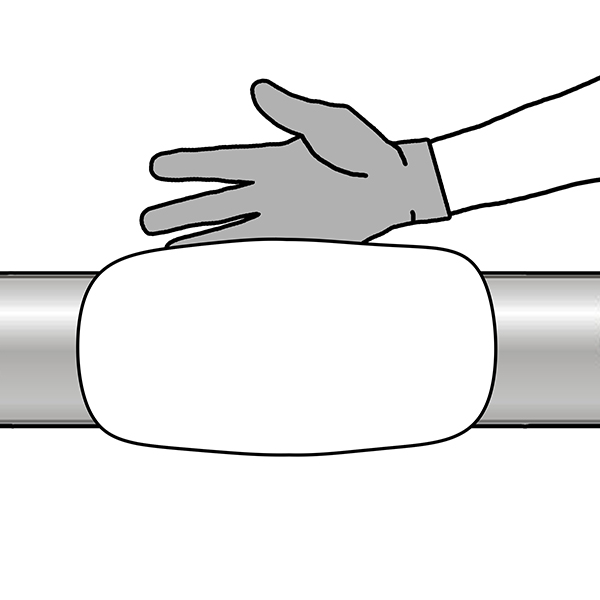

| Continue to polish the wrap until all bubbling has stopped. Repair completed with smooth and hard ivory appearance |

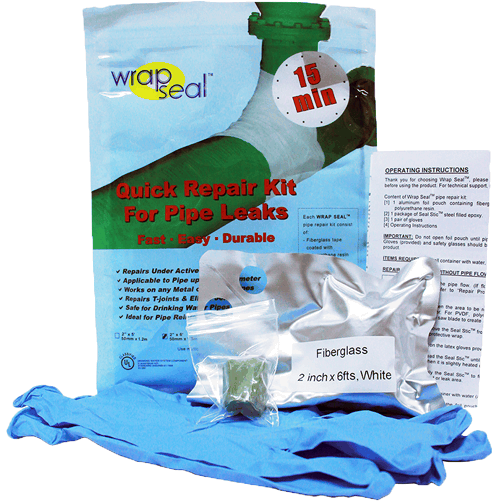

WRAP SEAL QUICK REPAIR KIT FOR PIPE LEAKS

PACKAGE:

- 1 roll of Wrap Seal Fiberglass Tape

- 2″ x 5′ (50 mm x 1.2 m)

- 2″ x 6′ (50 mm x 1.8 m)

- 2″ x 12′ (50 mm x 3.6 m)

- 3″ x 9′ (75 mm x 2.7 m)

- 4″ x 12′ (100 mm x 3.6 m)

- 1 unit of Seal Stic Quick Cure Epoxy

- 1 pair of latex gloves

- Operating instruction